August 2021 show notes

Story 1: Scientists create a new wearable device that turns your sweaty finger into a battery

Source: C/Net Story by Meara Isenberg

Link: https://www.cnet.com/news/this-wearable-device-turns-your-sweaty-finger-into-a-battery/

Nanoengineering scientists at UC San Diego have come up with a device that uses sweat from your fingertip to generate power.

Fun fact: Our fingertips are packed with more than a thousand sweat glands. And can produce between 100 to 1,000 times more sweat than most other body parts.

The scientists at UC San Diego created a flexible, thin strip that wraps around the tip of a finger like a Band-Aid and converts chemicals found in human sweat

into small amounts of electrical energy.

Fingers constantly produce sweat, so the device can work without the user moving a muscle.

Reality check: The device can potentially power electronics that operate in the milliwatt range, such as a wristwatch, but it’s not yet suitable for continuously powering electronics such as a smartphone.

But, maybe these fingertip strips could generate enough power to run small health monitoring devices.

Story 2: Jeff Bezos Is Building a 10,000-Year Clock Inside a Mountain

Source: Popular Mechanics Story by Caroline Delbert

Link: https://www.popularmechanics.com/science/a31156395/jeff-bezos-clock-long-now-mountain/

My son-in-law Brian turned me on to this story.

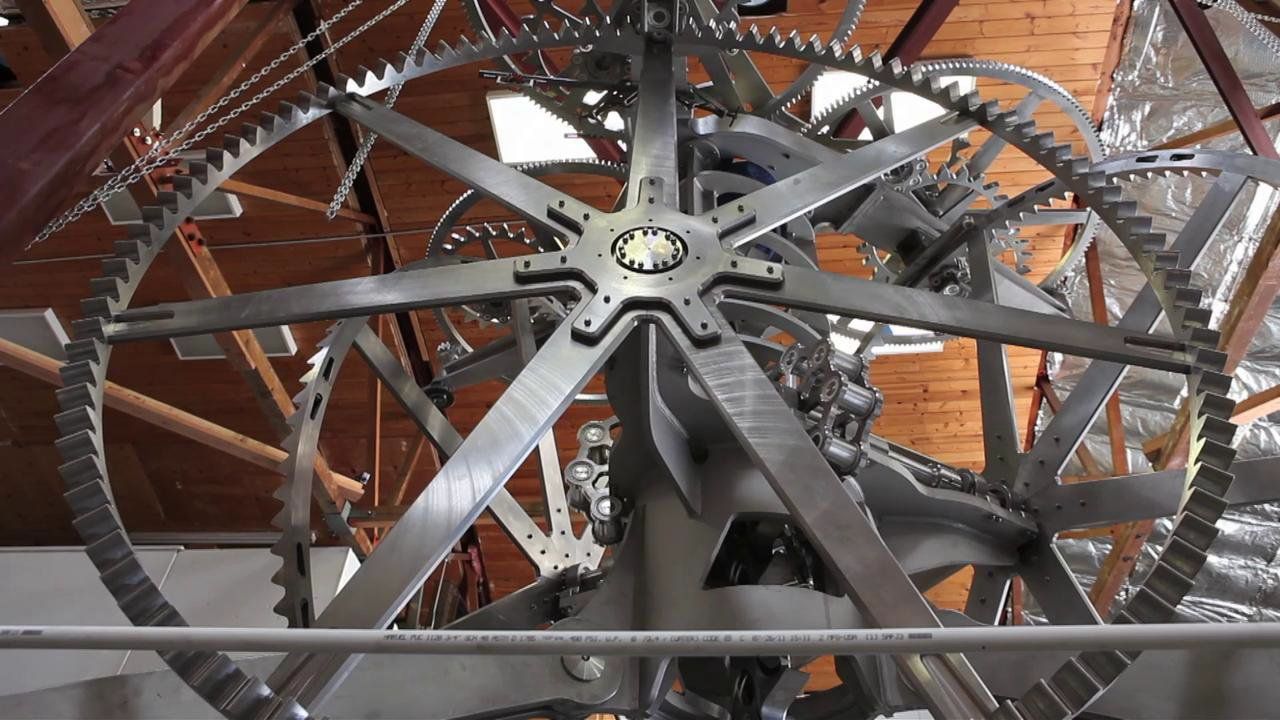

Jeff Bezos, Amazon founder, and his scientist friend Danny Hillis are building a

massive, multi-room clock inside a mountain on Bezos’s property in West Texas that will tell time for the next 10,000 years.

Danny Hillis, a visiting professor at the MIT Media Lab, is a computer scientist who first imagined the 10,000-year clock in 1986.

The clock is designed to tick just once a year and chime once per millennium.

According to Bezos, the clock will be 500 feet tall, and will be “all mechanical, and powered by day and night thermal cycles,” and “synchronized at solar noon.”

Solar noon is the moment when the Sun passes a location’s meridian and reaches its highest position in the sky. In most cases, it doesn’t happen at the 12 o’clock point on our watches and clocks.

Story 3: A new modified yeast can make ethanol from cornstalks and other leftovers

Source: ScienceNews.com Story by Nikk Ogasa

Link: https://www.sciencenews.org/article/genetically-modified-yeast-ethanol-cornstalk-biofuel

We’re all familiar with ethanol fuel made from corn kernels. But what about the rest of the plant as a source for biofuel?

When corn farmers harvest their crop, they often leave the stalks and leaves to rot in the fields.

Now, engineers at the Massachusetts Institute of Technology have developed a new strain of yeast that can convert this corn plant waste into ethanol.

Previous efforts to convert corn plant waste into fuel had very limited success.

That’s because existing yeasts could only start the process of converting corn plant waste into ethanol.

The problem was that when existing yeasts started to break down the corn plant waste the process often generated by-products that would kill the yeasts.

But by tweaking a gene in common baker’s yeast, MIT scientists have engineered a strain that can defuse those deadly by-products and get on with the job of turning the sugar in the corn plant waste into ethanol.

However, the researchers say that many more improvements are needed before this technology becomes commercially viable.

Story 4: New high-speed, driverless passenger pods that travel above ground could help cities solve traffic congestion

Source: CNN Business Story by: Ana De Oliva

Link: https://www.cnn.com/2021/07/08/tech/usky-pod-sharjah-uae-spc-intl/index.html

A Belarus-based company called uSky Transport recently opened a 400-meter experimental line of all-electric driverless passenger pods in the United Arab Emirates that can travel up to 93 miles per hour suspended above the ground on cables.

The 4-passenger, electrically powered prototype pods offer luxurious interiors including mood lighting, music, and floor-to-ceiling windows.

The uSky Transport team claims that a city-wide network of their suspended pods could support up to10,000 passengers per hour.

And, according to uSky Transport, while one kilometer of subway can cost up to $150 million to construct, their above ground pod transport system costs around $10 million per kilometer to build.

Story 5: New Battery-Free Wireless Cardiac Pacemaker Dissolves After Treatment

Source: Medgadget.com Story by Conn Hastings

Link: https://www.medgadget.com/2021/06/battery-free-wireless-pacemaker-dissolves-post-treatment.html

See video here: https://www.youtube.com/watch?v=cx-DyVZg4o0

A team of researchers headed up by scientists at Northwestern University has developed a temporary cardiac pacemaker that dissolves away in the body, turning into harmless byproducts.

This new technology is also wireless and battery-free and can be safely sealed into the body, with no need for later removal.

This wireless breakthrough eliminates the need to have lead wires poking out of a patient’s skin.

The current prototype of this new pacemaker is thin and flexible and lasts for approximately 5–7 weeks before breaking down into biocompatible byproducts that are eventually excreted by the body.

It also offers the option to tweak the formulation and structure of the device to precisely control how long it takes to dissolve, allowing doctors to customize the device to meet the needs of each patient.

And, to eliminate the need for a battery, the new device uses an external antenna to provide wireless energy to the dissolvable pacemaker.

Story 6: A Dutch company has created snap together road modules made with recycled plastic

Source: Redshift.com from Autodesk Story by Friederike Voigt

Link: https://redshift.autodesk.com/plastic-roads

A Dutch startup called PlasticRoad is now producing prototype sustainable roads made out of recycled plastic.

The PlasticRoad team claims, as compared to traditional asphalt roads, their modular plastic roads are:

easier to maintain,

can fully manage flooding,

and can be recycled, as needed, up to seven times.

And a roadway made with the company’s PlasticRoad sections is also:

four times lighter than traditional asphalt roads,

is 70% faster to build, and lasts three times longer than an asphalt road,

and produces up to 72% fewer carbon emissions in the process of construction than conventional roads.

Each modular, prefabricated lane section contains nearly 2,200 pounds of recycled plastic—the equivalent of 218,000 plastic cups.

And building a roadway with these plastic modular sections requires:

no intensive excavation work,

no heavy foundations,

and no environmentally detrimental concrete slabs and layers of asphalt,

With this technology, assembling a road is like playing with LEGO bricks: It takes just a few clicks after a module section is lowered into place to connect it to another section.

Two pilot projects—a pair of bicycle paths built in two Dutch towns—are now demonstrating the benefits of this innovative and sustainable alternative to traditional road construction.

Story 7: Severely paralyzed man communicates using brain signals sent to his vocal tract

Source: Engadget.com Story by Steve Dent

See video here: https://www.youtube.com/watch?v=_GMcf1fXdW8

Back in May we talked about an amazing technology that allowed a paralyzed

man to write individual letters, one at a time, on a computer screen using only his thoughts.

Now a severely paralyzed man can communicate using a new technology breakthrough that translates signals from his brain directly to his vocal tract to generate full words on a screen.

Developed by neuroprosthetic technology researchers at UC San Francisco, the technique is a more natural way for people with speech loss to communicate than other methods developed to date.

Here’s how it works:

The system uses an implant that’s placed directly on the part of the brain dedicated to speech.

The paralyzed subject can then mentally activate the brain patterns they would normally use to say a word.

And the system translates the entire word, rather than single letters, in real time and displays words on a computer screen.

Story 8: Oscillating Magnetic Field Shrinks a Brain Tumor

Source: Medgadget.com Story by Conn Hastings

Link: https://www.medgadget.com/2021/07/oscillating-magnetic-field-shrinks-glioblastoma-tumor.html

At the Houston Methodist Neurological Institute, researchers developed a headset device that generates a magnetic field that successfully shrank a glioblastoma brain tumor in a patient volunteer.

Glioblastoma is a brain cancer with a very poor prognosis, and which nearly always proves fatal.

The device the researchers created is worn on the head each day during treatment and uses an oscillating magnetic field to disrupt biochemical processes in cancer cells and kill them.

While the technique is in its infancy, this first-in-human test of this particular type of device shows promise and could herald the first steps in a new non-invasive treatment process.

The magnetic fields can be applied through a wearable headset, which helps to ensure that the treatment is localized near a glioblastoma tumor, and also means that patients can administer the therapy themselves at home.

The device consists of three oscillators attached to a helmet.

In this first-in-human test of the new device, a 53-year-old glioblastoma patient used the device regularly.

Unfortunately, the patient died after a month of treatment from an unrelated injury.

But an autopsy found that the treatment had shrunk the brain tumor by 31%

Story 9: World’s first commercial housing project based on 3D-concrete printing

Source: CNN

Link: https://www.cnn.com/style/article/3d-printed-house-scli-intl/index.html

A couple in Holland are the owners of what is claimed to be the first home in the world’s first commercial housing project that was created using 3D-concrete printing.

The single-story, 1,000 square foot house is the first from Project Milestone, a joint construction project from the Eindhoven University of Technology in the Netherlands.

The 3D printed home consists of 24 concrete elements, or modules.

Each component, or element, was printed layer-by-layer at a factory in Eindhoven.

The factory-based, computer guided large scale 3D printer consists of a huge robot with a mechanical arm that can move on a track in seven different directions to lay mortar in a pattern on a print bed.

The entire home modular components took only 120 hours to print.

Once printed, the modular house elements were transported by truck to the building site and assembled on a foundation.

Story 10: New fabric passively cools whatever it’s covering

Source: arsTechnica Story by John Timmer

For many years scientists have been studying materials that enable what’s called passive cooling.

Without using energy, these materials take heat from whatever they’re covering and radiate it out to space.

Most of these efforts have focused on building materials, with the goal of creating roofs that can keep buildings a few degrees cooler than the surrounding air.

But now a team of researchers in China has taken the same principles and applied them to fabric, creating a vest that keeps its users about 37.4 degrees Fahrenheit cooler than they would be otherwise.

The new passive cooling material is designed so that it reflects most of the incoming light, keeping stray photons from heating the person the material covers.

To make the clothing reflective, the researchers used a titanium dioxide powder,

which is highly reflective and often used to create things like white paint.

The researchers took titanium dioxide nanoparticles and embedded them in polymer fibers, choosing the size of the particles based on computer modeling to maximize reflection.

The experimental fabric reflected well over 90 percent of incoming sunlight.

Story 11: Desalination Membrane System Can Make Seawater Drinkable in Minutes

Source: SciTechDaily

Story from National Research Council of Science & Technology

The Korea Institute of Civil Engineering and Building Technology has announced the development of a new electrospun nanofiber membrane that can turn seawater into drinking water in minutes by using a membrane distillation process.

The team hopes this new desalination technology can help solve the world’s freshwater shortage.

The research team developed a new breakthrough co-axial, nanofiber membrane fabricated using a process called electrospinning.

Electrospinning is a process in which ultrathin, multifilament fibers with diameters in the nanometer range are created by spinning and manipulating streams of electrically charged polymers in a strong magnetic or electric field.

For example, electrospinning is used to make specialized fabrics, such as those in spacesuits.

Previous attempts around the world to use electrospun nanofiber membranes for desalination systems resulted in equipment that could operate for less than 50 hours.

The Korea Institute of Civil Engineering and Building Technology’s new system operated successfully for 30 days, yielding 99.99% removal of salt from sea water.

Story 12: A Cousin of Table Salt Could Make Rechargeable Batteries Faster and Safer

Source: SciTechDaily Story from Oak Ridge National Laboratory

Link: https://scitechdaily.com/a-cousin-of-table-salt-could-make-rechargeable-batteries-faster-and-safer/

One of the biggest factors affecting consumer adoption of electric vehicles is the amount of time required to recharge the vehicles—usually powered by lithium-ion batteries.

It can take up to a few hours or overnight to fully recharge EVs.

Today’s rechargeable lithium-ion batteries charge only at slower, controlled rates – which is a safety feature to help prevent fires, and even explosions.

Recently researchers from the University of California San Diego worked with scientists at Oak Ridge National Laboratory find a better solution.

They conducted neutron scattering experiments on a new type of material that could be used to make safer, faster-charging lithium-ion batteries.

The researchers produced samples of lithium vanadium oxide which is a “disordered rock salt” similar to table salt but with a certain degree of randomness in the arrangement of its atoms.

During testing, the rock salt anode material was able to deliver more than 40 percent of its energy capacity in just 20 seconds of after voltage charging.

The rapid charging and discharging appear possible because the rock salt material can rapidly cycle two lithium ions in and out of vacant sites within its crystal structure.

Story 13: New Fully Autonomous AI-Powered Beehive Could Help Save Bee Colonies

Source: Forbes Story by Jennifer Kite-Powell

Link: https://bit.ly/3fXHaHG

Here’s the problem today with our bee population worldwide.

With a 35% global annual decline of bee colonies that support 75% of crops, we’re facing an immediate and serious threat to the global food supply.

Preventing bee colonies from collapsing allows for more pollination.

To help save bee colonies, Beewise, an agricultural tech startup, has created the first fully autonomous beehive called Beehome.

The Beehome system comes complete with a beekeeping robot that acts as both medic and guardian to complement the natural intelligence of bees.

The Beehome system utilizes artificial intelligence, machine learning and precision robotics to rescue and protect a hive’s bees.

The modular commercial AI-powered robotic apiary also has 24/7 monitoring and smart technology that increases pollination capacity and honey production.

The system is entirely solar-powered and manages 24 hives and automates their operation such as pollination, honey-production, and reproduction.

The Beehome system also includes:

an automated robotic brood box management system,

a computer vision-based monitoring system,

AI-based decision making and predictive analytics,

automated honey harvesting system,

and an automated system for pest control, feeding and thermoregulation.

Story 14: A Scotch Distiller Is Fueling Its Trucks with Whisky Waste

Source: InterestingEnginnering.com Story by Chris Young

Link: https://interestingengineering.com/a-scotch-distiller-is-fueling-its-trucks-with-whisky-waste

Scotland’s whisky industry has collectively announced plans to reach net-zero emissions.

Scotch whisky maker Glenfiddich, which sells over 14 million bottles of single malt whisky annually, started modifying its delivery trucks to run on low-emission biofuel, in gas form, made out of waste products from its own whisky distilleries.

Glenfiddich stated that it has built fueling stations at its Dufftown distillery in north-eastern Scotland, specially designed to convert whisky production waste and residues into Ultra-Low Carbon Fuel.

The distiller claims that the biogas reduces the C02 emissions of its trucks by over 95 percent, as well as curbing other harmful particulates and greenhouse emissions by 99 percent when compared to its diesel delivery vehicles.

Glenfiddich believes that each of its biogas-fueled trucks will have the capacity to displace close to 250 tons of CO2 in a year.