Show Notes December 8, 2023

Story 1: World’s first autonomous turbogenerator-hybrid electric vertical takeoff and landing aircraft takes flight

Source: Interesting Engineering Story by Can Emir

Link: https://interestingengineering.com/transportation/chaparral-c1-turbogenerator-hybrid-hvtol

See video here: https://www.youtube.com/watch?v=i7c9ehwExIw

- Cargo drone startup Elroy Air has achieved a groundbreaking milestone with the successful test flight of its Chaparral C1, an autonomous turbogenerator-hybrid electric vertical take-off and landing (hVTOL) aircraft.

- The historic flight occurred on November 12 at the company’s test-flight facility in Byron, California.

- Elroy Air’s Chaparral C1 is not just a conventional cargo drone; it represents a significant leap forward in the aviation industry, combining distributed electric propulsion (DEP) with a turbogenerator-battery architecture. This innovative approach enables the aircraft to achieve vertical take-off, autonomous flight, and safe landing, marking a pivotal moment in developing hybrid-electric aircraft.

- Hybrid-electric powertrains represent a critical advancement in the aviation industry, balancing battery and turbogenerator power output. This balance is crucial for responding to load demand and ensuring effective and efficient flight.

- Elroy Air’s Chaparral C1 addresses the limitations of all-electric systems by combining a gas turbine-driven generator with batteries. This turbogenerator-hybrid architecture enables long-range missions without charging infrastructure, making it an ideal solution for logistics, humanitarian aid shipping, and military resupply.

- Following the groundbreaking test flight, Elroy Air is embarking on an ongoing envelope expansion campaign in collaboration with the US Air Force. This campaign will advance Chaparral C1’s demonstrated flight capabilities through various modes of airborne operations, including expanded hover, system identification, transition, and cruise flight.

- Elroy Air’s vehicle backlog currently exceeds $3 billion in future revenues.

Story 2: Engineers develop an efficient process to make fuel from carbon dioxide

Source: MIT News Story by David L. Chandler

Link: https://news.mit.edu/2023/engineers-develop-efficient-fuel-process-carbon-dioxide-1030

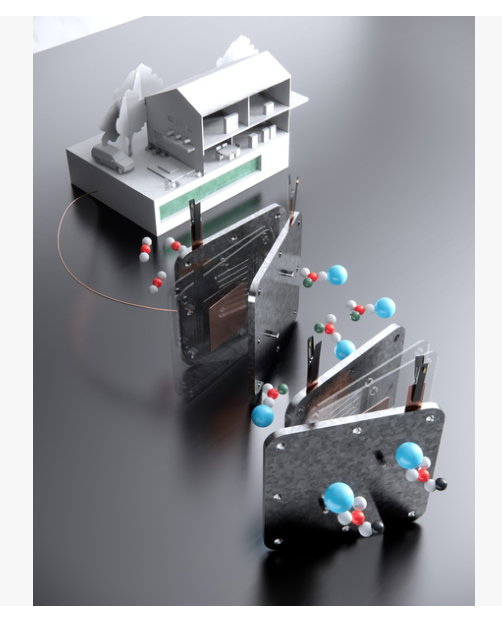

- Researchers at MIT and Harvard University have developed an efficient process that can convert carbon dioxide into formate, a liquid or solid material that can be used like hydrogen or methanol to power a fuel cell and generate electricity.

- Potassium or sodium formate is already produced at industrial scales and commonly used as a de-icer for roads and sidewalks. It is nontoxic, nonflammable, easy to store and transport, and can remain stable in ordinary steel tanks to be used months, or even years, after its production.

- The new process, developed by MIT and Harvard doctoral students; and MIT Professor Ju Li, is described in an open-access paper in Cell Reports Physical Science.

- The whole process — including capture and electrochemical conversion of the gas to a solid formate powder, which is then used in a fuel cell to produce electricity — was demonstrated at a small, laboratory scale.

- However, the researchers expect it to be scalable so that it could provide emissions-free heat and power to individual homes and even be used in industrial or grid-scale applications.

- Here’s why this is a big breakthrough – Other approaches [to date] for converting carbon dioxide into fuel usually involve a two-stage process:

- First the gas is chemically captured and turned into a solid form as calcium carbonate, then later that material is heated to drive off the carbon dioxide and convert it to a fuel feedstock such as carbon monoxide.

- That second step has very low efficiency, typically converting less than 20 percent of the gaseous carbon dioxide into the desired product.

- By contrast, the new MIT and Harvard process achieves a conversion of well over 90 percent and eliminates the need for the inefficient heating step by first converting the carbon dioxide into an intermediate form, liquid metal bicarbonate.

- The liquid metal bicarbonate is then electrochemically converted into liquid potassium or sodium formate in an electrolyzer that uses low-carbon electricity, e.g. nuclear, wind, or solar power.

- The highly concentrated liquid potassium or sodium formate solution produced can then be dried, for example by solar evaporation, to produce a solid powder that is highly stable and can be stored in ordinary steel tanks for up to years or even decades.

Story 3: Inactive bacteria powers self-healing concrete to repair cracks

Source: Interesting Engineering Story by Mrgakshi Dixit

Link: https://interestingengineering.com/innovation/bacteria-powers-self-healing-cracks

- Concrete is highly susceptible to the relentless forces of nature, resulting in the formation of cracks.

- Now, imagine a construction material capable of self-healing. While this might sound like a concept from the future, researchers at Drexel University have turned this idea into reality through the creation of an advanced self-healing concrete.

- They have created a novel concrete technology called “BioFiber” that leverages the power of some bacteria to mend cracks as they form due to constant weathering.

- This revolutionary concrete has the potential to greatly enhance building industry sustainability.

- As infrastructure deteriorates naturally over time, it may need time-to-time repair. Temperature changes and moisture exposure aggravate this process, causing fissures to spread and the concrete to erode.

- The requirement for regular maintenance may be both costly and environmentally demanding, contributing to a higher carbon footprint.

- As per the official release, the BioFibers demonstrate three key capabilities: a self-repairing mechanism, control over widening fractures, and effective damage response.

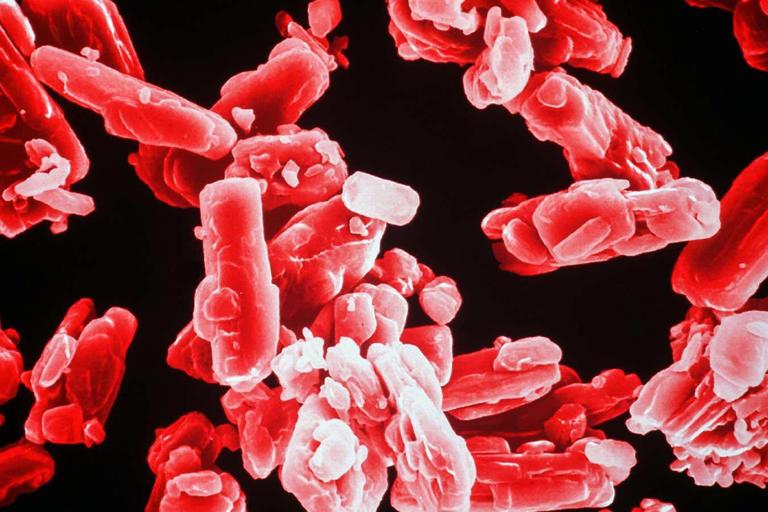

- They are made of a core fiber surrounded by a hydrogel sheath containing dormant bacterial spores, all encased in a polymeric outer shell. When a crack forms in the concrete and ruptures the BioFiber, water penetrates and causes the hydrogel to swell and the bacteria to produce calcium carbonate, which seals the crack, healing the damage in the concrete.

- The authors made comparisons to human tissue’s inherent self-healing characteristics, noting that BioFibers imitate this concept by employing bacteria to generate damage-responsive living self-healing concrete.

- The study was published in the journal Construction and Building Materials.

Story 4: One-time CRISPR treatment could permanently lower cholesterol

Source: New Scientist Story by Michael Le Page

- A CRISPR gene-editing treatment has lowered cholesterol levels in a small, initial trial involving 10 people. The effect has lasted for six months since the first participant was treated, and the expectation is that it will be permanent – but a heart attack in one person has raised safety concerns.

- The trial, carried out in New Zealand, involved people with an inherited disease that results in very high cholesterol levels and so a very high risk of heart disease. However, the company developing the treatment, Verve Therapeutics in Boston, hopes its one-off treatment could eventually replace cholesterol-lowering drugs like statins.

- In the three people given the highest doses, levels of LDL cholesterol (LDL-C), which is linked to heart disease risk, fell between 39 and 55 per cent.

- Reality check – For now, though, questions remain about safety. One of the three people who received a high dose had a heart attack a day after being treated that might have been related to the treatment, but could also have been due to their underlying disease, Verve Therapeutics said in a press release announcing the results.

HONORABLE MENTIONS:

Story: Researchers discover common mineral could unlock ‘superior’ energy storage in EV batteries

Source: The Cool Down Story by Rick Kazmer

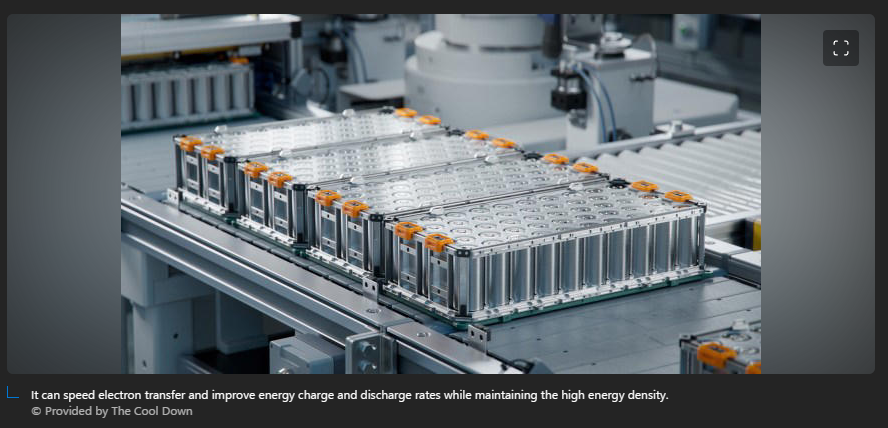

- Battery tech experts in China are researching alternative chemistry that they said provides “superior” energy storage in power packs.

- Iodine is the element that unlocked the breakthrough, which could pave the way for power packs with “stability, long life, and low levels of energy loss during storage,” according to a report on the science from TechXplore.

- The experts, from the Qingdao Institute of Bioenergy and Bioprocess Technology of the Chinese Academy of Sciences, are working on lithium thionyl chloride batteries with a liquid electrolyte. The electrolyte is the solution in the battery cells where particles pass back and forth during the charge/discharge cycle, per a lab report from ACS Publications.

- Outside the battery, the National Library of Medicine notes that thionyl chloride is a “colorless to yellow fuming liquid with a suffocating pungent odor.”

- Inside the battery, it helps create the chemistry needed for energy storage. The result “has great potential to meet the ever-increasing demand of energy-storage systems,” according to the ACS report.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Say Goodbye to Range Anxiety with This Solar-Powered Electric Scooter

Source: InsideEVs Story by Enrico Punsalang

Link: https://insideevs.com/news/674177/s80-solar-powered-electric-scooter/

See video here: https://www.youtube.com/watch?v=ve6hZSBgEc0

- Here in the world of micromobility, we’ve seen our fair share of e-bikes and e-scooters attempt to harness the power of solar in a bid to eliminate range anxiety for good. The newest of which comes in the form of the S80 Solar Scooter, developed by a Chinese company called Jiangsu Snail Zhixing Technology. Electrek was at the Eurobike 2023 trade show and got to see the solar-powered scooter firsthand (be sure to check out the article below), and it goes without saying that this scooter will be a head-turner on the road.

- According to the Electrek article, the S80 Solar Scooter takes between seven and 14 hours of sunlight to fully charge. It offers between 35 to 70 watts of power to charge the onboard battery, and each charge is good for an impressive 22 miles. Assuming you live in the city, that’s quite a lot of range for you to get to work and back on a daily basis. Assuming it’s a sunny day, and you park your S80 outside, you’ve pretty much got yourself a scooter that’ll never run out of juice – provided the weather cooperates, that is.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Einride’s drone truck has its first full-time job moving GE appliances around

Source: The Verge Story by Umar Shakir

- The Swedish autonomous trucking company Einride is using its cab-less electric delivery vehicles in Selmer, Tennessee, to move items from GE Appliances’ manufacturing plant to a warehouse. This operation can run up to seven shuttles per day, Monday through Thursday, the press release states. In an email to The Verge, a PR representative for Einride, Matthew Klein, wrote that the distance for each trip is 0.3 miles (or 0.48km) and is all on private roads owned by GE.

- Einride first ran controlled operations at GE’s Appliance Park headquarters in 2021. Later, the company moved on to a public road test with National Highway Traffic Safety Administration approval in 2022, the “first public road pilot in the US for a purpose built autonomous, electric truck without a driver on board.”