Show Notes December 22, 2023

Story 1: Researchers fuse lab-grown human brain tissue with electronics

Source: Popular Science Story by Andrew Paul

See also: https://newatlas.com/computers/hybrid-brain-organoid-computing/

Indiana University source: https://blogs.iu.edu/iuimpact/2023/12/15/human-brain-tissue-on-a-computer-chip-iu-bioengineers-are-building-the-intersection-of-organoids-and-ai/

See video here: https://www.msn.com/en-us/video/health/scientists-produce-computer-made-from-lab-grown-human-brain-cells/vi-AA1lnNDX?t=8

- Your biological center for thought, comprehension, and learning bears some striking similarities to a data center housing rows upon rows of highly advanced processing units. But unlike those neural network data centers, the human brain runs on an electrical energy budget.

- On average, your brain functions on roughly 12 watts of power, compared with a desktop computer’s 175 watts. For today’s advanced artificial intelligence systems, that wattage figure can easily increase into the millions.

- Knowing this, researchers at the Indiana University Luddy School of Informatics, Computing and Engineering, believe the development of cyborg “biocomputers” could eventually usher in a new era of high-powered intelligent systems for a comparative fraction of the energy costs. And they’re already making some huge strides towards engineering such a future.

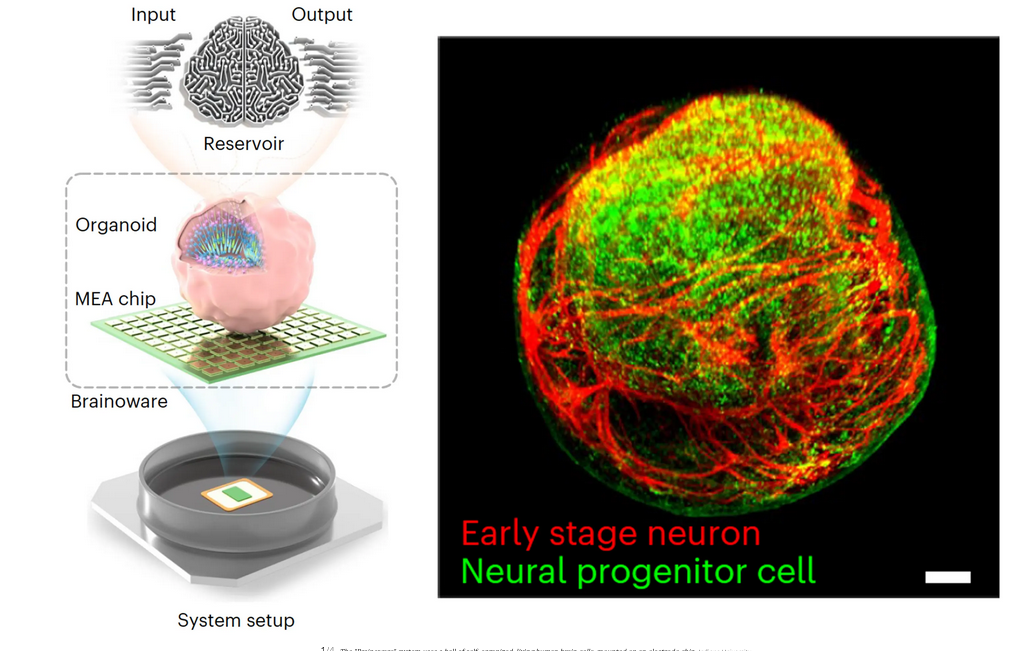

- As detailed in a new study published December 11 in Nature Electronics, the Indiana University team reported they had successfully grown their own nanoscale “brain organoid” in a Petri dish using human stem cells. After connecting the organoid to a silicon chip, the new biocomputer (dubbed “Brainoware”) was quickly trained to accurately recognize speech patterns, as well as perform certain complex math predictions.

- As the news outlet New Atlas explains, researchers treated their Brainoware as what’s known as an “adaptive living reservoir” capable of responding to electrical inputs in a “nonlinear fashion,” while also ensuring it possessed at least some memory.

- Simply put, the lab-grown brain cells within the silicon-organic chip function as an information transmitter capable of both receiving and transmitting electrical signals.

- While these feats in no way imply any kind of awareness or consciousness on Brainoware’s part, they do provide enough computational power for some interesting results.

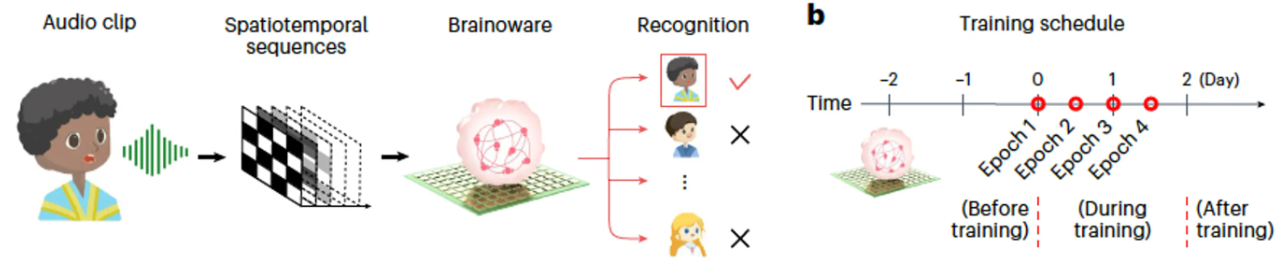

- To test out Brainoware’s capabilities, the team converted 240 audio clips of adult male Japanese speakers into electrical signals, and then sent them to the organoid chip. Within two days, the neural network system partially powered by Brainoware could accurately differentiate between the 8 speakers 78 percent of the time using just a single vowel sound.

- Next, researchers experimented with their creation’s mathematical knowledge. After a relatively short training time, Brainoware could predict a Hénon map. While one of the most studied examples of dynamical systems exhibiting chaotic behavior, Hénon maps are a lot more complicated than simple arithmetic, to say the least.

- Time out, what is a Hénon map? In mathematics, the Hénon map is a discrete-time dynamical system. It is one of the most studied examples of dynamical systems that exhibit chaotic behavior. Source: https://en.wikipedia.org/wiki/H%C3%A9non_map

- In the end, Brainoware’s designers believe such human brain organoid chips can underpin neural network technology, and possibly do so faster, cheaper, and less energy intensive than existing options.

- Reality Check: There are still a number of hurdles—both logistical and ethical—to clear, but although general biocomputing systems may be years down the line, researchers think such advances are “likely to generate foundational insights into the mechanisms of learning, neural development and the cognitive implications of neurodegenerative diseases.”

- My reality check issue – how would you keep the brain tissue “alive”?

Story 2: Profuse Technology achieves 80% faster muscle growth for [lab grown] cultivated meat

Source: The Jerusalem Post Story by Zachy Hennessey

Note: this news came out in September, but I think it is an important development to share!

- Profuse Technology, a front-runner in the field of muscle-tissue growth, has made significant strides that could have far-reaching implications for the cultivated meat and life-science sectors. The company’s latest developments have led to an impressive 80% reduction in the time required for muscle growth, achieving maturity in just 48 hours.

- This acceleration not only quickens the growth process but also enhances the protein content of muscle tissue by a factor of five, providing a healthier and more protein-rich alternative to traditional meat sources.

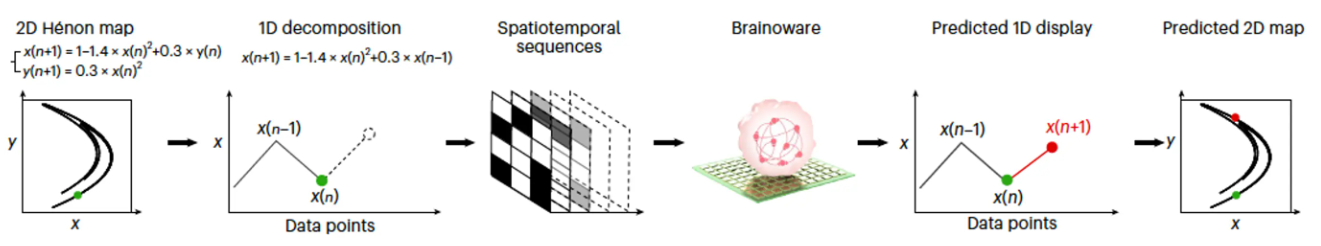

- Traditional cell cultures are typically grown in a flat, two-dimensional environment (2D). In contrast, 3D growth methodologies [which Profuse Technology uses] involve creating a three-dimensional environment, where cells can interact and grow in a more realistic and physiologically relevant manner.

- This approach aims to mimic the complex structure of natural tissues and organs, allowing cells to develop and mature in a manner that closely resembles their behavior in a living organism.

- In the context of muscle-tissue production, 3D growth methodologies involve providing an environment where muscle cells can form intricate three-dimensional structures, similar to the muscle fibers found in traditional meat. This method enables the development of muscle tissue that not only grows faster, but also exhibits characteristics more akin to natural muscle.

- My note – Profuse Technology did not invent 3D printing of lab grown meat. Many other outfits are developing this. The key to this news is the speed of production they have achieved [achieving maturity in just 48 hours].

- How this 3D growth approach works:

- First scaffolds – Scaffolds are supportive structures or frameworks made from biocompatible materials. They serve as a foundation for cells to attach to and grow upon in three dimensions. In muscle tissue production, scaffolds are designed to mimic the extracellular matrix found in living organisms.

- Second microcarriers – Microcarriers are small particles that can be suspended in a culture medium. They provide a surface for cells to attach and grow within a bioreactor or culture vessel and are particularly useful when working with large-scale cell cultures, as they increase the surface area available for cell attachment and can enhance the efficiency of nutrient exchange. In the context of muscle-tissue production, microcarriers can be engineered to support the growth and organization of muscle cells within a 3D environment.

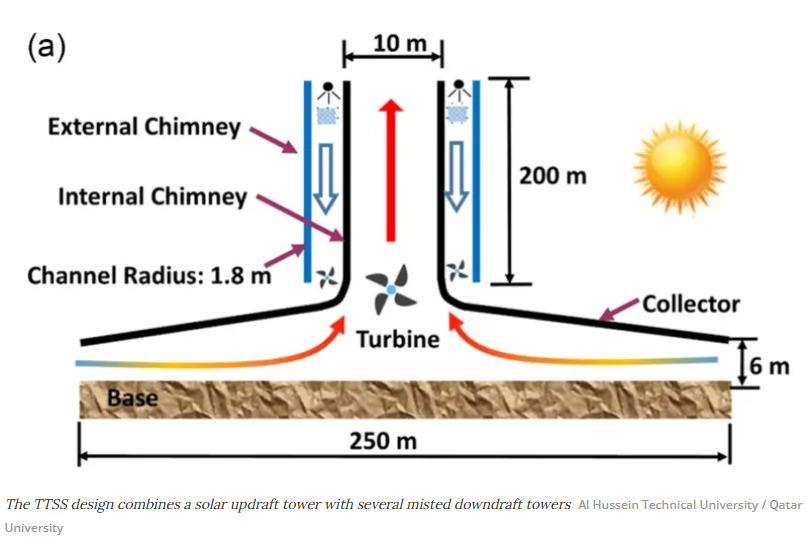

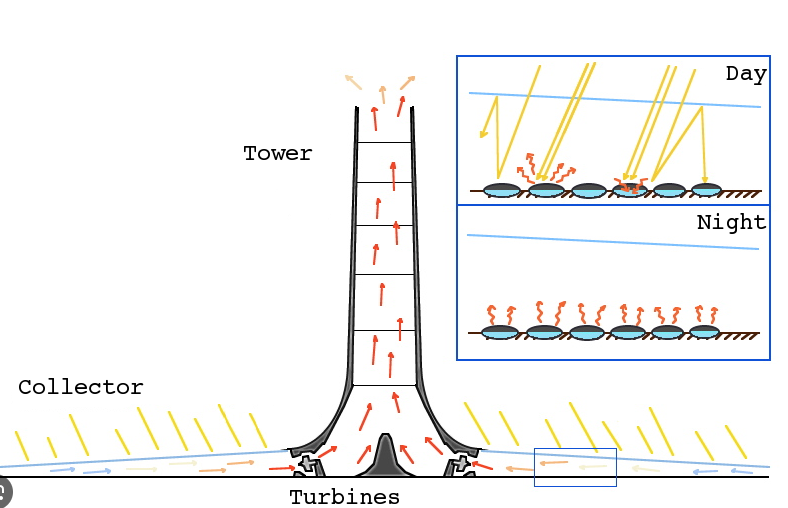

Story 3: Double-action solar tower promises clean energy all day and night

Source: New Atlas Story by Loz Blain

Link: https://newatlas.com/energy/double-solar-updraft-cooling/

- Researchers in Jordan and Qatar have come up with a remarkable design [concept] for a “twin technology solar system” capable of generating clean energy 24/7. This double-action design promises more than twice as much energy as a standard solar updraft tower.

Standard Solar Updraft Tower

- As its name suggests, the twin technology solar system combines two tower-style technologies into a single design: a solar updraft tower and a cooling downdraft tower. These are integrated into a single tower, with the updraft tower coming up through the middle.

- A solar updraft system works by heating up the air at ground level, then using the fact that hot air rises to funnel that air up a tall tower with turbines in it. The air is heated under a large roof covering a vast [ground level] collection area, made from a greenhouse-type material designed to trap as much heat as possible.

- A cooling downdraft tower, on the other hand, forces air downwards to turn another turbine. In this design proposed by researchers in Jordan and Qatar, that’s accomplished by spraying a fine mist of water into the ambient air at the top of the tower, making it both cooler and heavier and sending it downward.

- The proposed twin technology solar system design places an updraft tower in the middle and surrounds it with 10 downdraft towers running around the outside, such that it can operate in both updraft and downdraft modes simultaneously.

- In simulation testing using local weather data, the team estimated that such a system would generate a total of around 753 megawatt-hours of energy annually:

- With the external downdraft towers running around the clock to deliver about 400 megawatt-hours.

- And the updraft tower working more efficiently under the hot sun to contribute around 350 megawatt-hours.

- Reality Check: To date these have been built at experimental scale, but not yet at a commercial scale, since they’re typically very large, tall structures to ensure a good temperature differential. Thus, capital costs are high, and they’re viewed as risky.

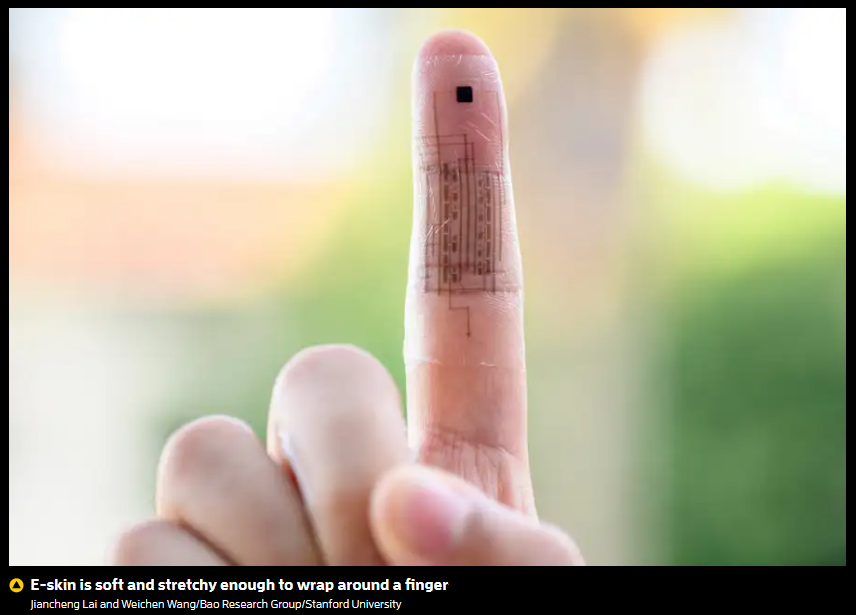

Story 4: Stretchy electronic skin responds to touch and pressure like real skin

Source: New Scientist Story by Karmela Padavic-Callaghan

- Researchers at Stanford University in California have developed a patch of artificial skin that can convert signals from pressure or heat sensors into brain signals – touching this electronic skin after it was connected to a rat’s brain spurred the rat to kick its leg. This could be used to improve prosthetics for people who have skin damage.

- The Stanford research team has created a device they call e-skin out of an electronic circuit and pressure and temperature sensors, all crafted out of a thin and stretchy rubbery material.

- The Stanford team merged these components into one patch that easily conforms to uneven surfaces, such as a human finger. E-skin works by imitating biological skin, where nerves detect pressure or warmth and then send sequences of electrical signals, or “pulse trains”, to the brain.

- When it was heated or when pressure was applied to it, the e-skin’s sensors sent signals into the circuit, which converted them into pulse trains. To do all this, the e-skin needed [only] up to 1/60th of the voltage used by older [to date] artificial skin devices.

- This could mean the e-skin won’t heat up as much, making it more comfortable for longer use. Any artificial skin that could be used as a prosthetic for people with skin injuries needs to be comfortable enough to wear for a long time.

- Skin sensations can trigger quick muscle movements, so the researchers connected the e-skin to the nervous system of a living rat to see whether it could do something similar.

- The team connected the electrodes in a patch of e-skin into the region of the rat’s brain that processes touch and temperature. They then put pressure on the device.

- The rat’s brain reacted by firing more signals between neurons in the region that controls movement. When the researchers routed those signals into the rat’s leg through an insertable artificial synapse device, it kicked.

- Side note – what is a synapse? A synapse is a small gap at the end of a neuron that allows a signal to pass from one neuron to the next. Neurons are cells that transmit information between your brain and other parts of the central nervous system. Synapses are found where neurons connect with other neurons.

- Reality check – according to an expert at Northeastern University in Massachusetts, “This is a clear demonstration: based on sensation, there were movements. And this is not a small thing, it’s quite challenging work to get the electronics to work well enough for this. However, the e-skin may need even more sophisticated circuity to be used in place of large areas of skin”.

HONORABLE MENTIONS:

Story: GE Aerospace cracks hypersonic engine test, claims 4,000mph achievable

Source: Interesting Engineering Story by Christopher McFadden

Link: https://interestingengineering.com/military/ge-low-mach-startup-ramjet

- General Electric Aerospace, a subsidiary of General Electric has announced that its engineers have successfully remote-tested its latest hypersonic engine.

- During the testing, the hypersonic dual-mode ramjet (DMRJ) engine, a detonating combustion engine in a ramjet, was set up on a rig. General Electric (GE) and other companies like Raytheon, who are working on this engine, believe it could enable faster, long-range flight with increased efficiency in hypersonic propulsion.

- Side Notes:

What is detonation in a combustion engine?

Detonation – Detonation, as the name suggests, is an explosion of the fuel-air mixture inside the cylinder. It occurs after the compression stroke near or after top dead center. During detonation, the fuel/air charge (or pockets within the charge) explodes rather than burning smoothly. Source: https://www.faasafety.gov/files/notices/2019/Jul/Preignition.pdf

What is meant by RAM jet?

A ramjet is a variant of an air breathing jet engine that does not include a rotary compressor; rather, it uses the engine’s forward motion to compress the incoming air. Source: https://skybrary.aero/articles/ramjet

- The test was conducted in a supersonic flow stream at the Global Research Center in Niskayuna, New York. This innovative engine has the potential to power hypersonic vehicles, allowing for greater efficiency and longer ranges, with the capability of achieving speeds exceeding Mach 5 (4,000mph).

- The GE Aerospace team has been working on the new DMRJ with remote detonating combustion (RDC) for the past year. GE explains that they plan to demonstrate a full-scale version of this system next year. Typically, air-breathing DMRJ propulsion systems require supersonic speeds of over Mach 3 to get going. However, GE Aerospace engineers are developing a rotating detonation-enabled dual-mode ramjet that can work more efficiently at lower Mach speeds. This innovation will enable air vehicles to achieve longer range and operate more efficiently.

- To the end, last year, GE Aerospace acquired Innoveering, a company specializing in hypersonic propulsion. GE Aerospace has combined its RDC and high Mach R&D expertise with Innoveering’s dual-mode ramjet engine capabilities. RDC technology enables more efficient fuel combustion using detonation waves, resulting in higher thrust generation, smaller engine size, and lighter weight than traditional jet engines.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

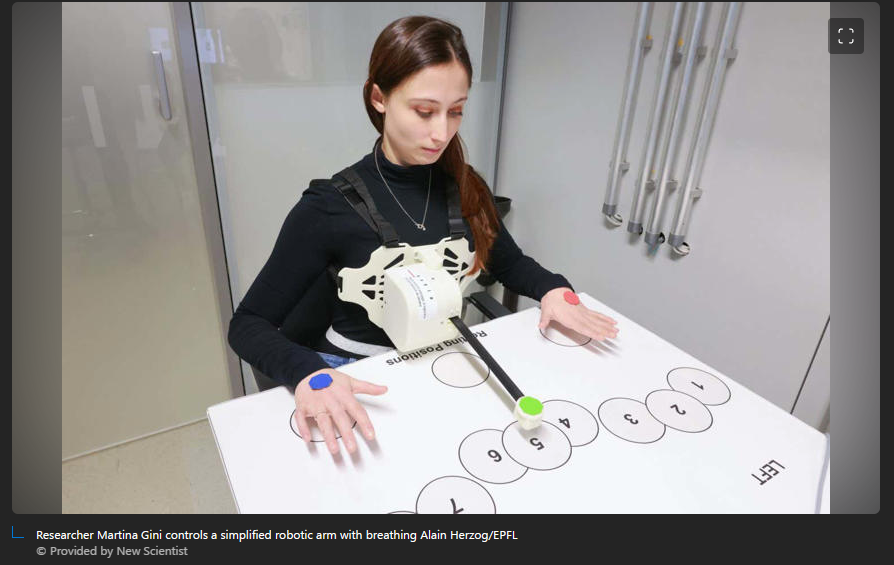

Story: Robotic third arm controlled by breathing is surprisingly easy to use

Source: New Scientist Story by Matthew Sparkes

See video here: https://www.youtube.com/watch?v=aJXVnPGCCck

- Giulia Dominijanni at the Swiss Federal Institute of Technology Lausanne and her colleagues created real robotic third arms and virtual ones inside VR environments, all controlled by a combination of eye movements and diaphragm contractions. In tests, 65 volunteers were able to successfully carry out a range of tasks without interfering with their normal breathing, speech, or vision.

- Unlike prosthetics for people with amputated limbs, which can attach to a stump and use existing nerve connections to the brain, augmented devices require entirely new connections and are therefore more difficult to engineer, says Dominijanni. But the experiments show that peoples’ brains are capable of adapting to these devices and controlling them quite intuitively.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: The growing field of fungus in low carbon, sustainable building materials

Source: Anthropocene.org Story by Prachi Patel

- Two new studies show how a lightweight construction material and a fire-retardant, both made from fungi, could be safe, sustainable alternatives to the chemicals, foams, and plastics in our homes.

- When you think about strong, fireproof materials for building homes, soft and spongy mushrooms are not the first thing that come to mind. But two new studies show how fungi could be used to make sustainable building materials that reduce the climate and environmental impact of our built environment.

- A team from Newcastle University in the UK and Vrije Universiteit Brussel in Belgium have grown fungus together with other ingredients to make a material they call myocrete, which can be used for lightweight construction. In another study, researchers from RMIT University in Australia engineered mycelium—the root-like network that is the foundation of fungal colonies—to create a sustainable fire-retardant material that could be used as building insulation or a leather substitute.