Show Notes 5 July 2024

Story 1: Energy company launches world’s first energy storage facility using molten salt.

Source: The Cool Down Story by Wes Stenzel

See also: https://interestingengineering.com/energy/world-first-molten-salt-energy-storage

See video here: https://www.youtube.com/watch?v=bbzr6sRks-w

- As we invest in solar and wind power infrastructure, it’s vital that we also find ways to store the extra energy that these technologies generate so we can make clean electricity more efficient, thereby driving down energy costs for homeowners and industries alike.

- A Danish energy company called Hyme Energy is launching a new energy storage system they call Molten Salt Storage (MOSS), which uses molten hydroxide salt to store excess clean energy. It’s the first project of its kind.

- Side note – What is hydroxide salt? It consists of an oxygen and hydrogen atom held together by a single covalent bond, carrying a negative electric charge.

- Sodium hydroxide (NaOH) is a widely used industrial alkali and is often found in drain and oven cleaners

- Hyme Energy developed the system to utilize excess energy from solar or wind power to heat hydroxide salt, melting it into a molten substance at super-hot temperatures.

- The molten salt is then stored at a high temperature and saved for a rainy day. Once there’s a period of lower clean wind or solar energy generation, the facility can unleash its stored salty heat as thermal energy that is converted into steam, which can provide electricity.

- Hyme Energy hopes to scale their Molten Salt Storage technology globally for industrial purposes and have it ready for sale by 2026.

- Other new developments in clean energy storage are using ice, mines, and even chicken fat to store extra clean energy.

- TIME OUT, chicken fat! – reminder from our May 17 podcast honorable mention – Researchers in South Korea have made an intriguing breakthrough by converting chicken fat into energy storage devices. They’ve developed a method to transform chicken fat into carbon-based electrodes for supercapacitors, which can store energy and power LEDs.

- Source: Poultry Power: Transforming Waste Chicken Fat into Clean Energy. https://scitechdaily.com/poultry-power-transforming-waste-chicken-fat-into-clean-energy/

Story 2: First-ever 3D printer that gulps plastic, metal, chips to make layered devices –Innovative 3D printing method streamlines multi-materials manufacturing

Source: Science Daily Story by University of Missouri

Link: https://www.sciencedaily.com/releases/2024/06/240624125422.htm

See also: https://optics.org/news/15/6/38

- University of Missouri researchers have developed a way to create complex devices with multiple materials — including plastics, metals and semiconductors — all with a single machine.

- The research, which was recently published in Nature Communications, outlines a novel 3D printing and laser process to manufacture multi-material, multi-layered sensors, circuit boards and even textiles with electronic components.

- It’s called the Freeform Multi-material Assembly Process, and it promises to revolutionize the fabrication of new products.

- For the public, applications could include wearable devices that monitor blood pressure and other vital signs.

- To date, other 3D printing techniques have fallen short when it comes to how versatile the input material can be and how precisely smaller components can be placed inside larger 3D structures.

- The University of Missouri team’s method uses special techniques to solve these problems. Team members built a single 3D printing machine that has three different nozzles:

- One adds ink-like material,

- Another uses a laser to carve shapes and materials,

- And the third adds additional functional materials to enhance the product’s capabilities.

- Here’s how it works:

- It starts by making a basic structure with regular 3D printing filament, such as polycarbonate, a type of transparent thermoplastic.

- Then, it switches to laser to convert some parts into a special material called laser-induced graphene, putting it exactly where it’s needed.

- Finally, more materials are added to enhance the functional abilities of the final product.

- This work is being funded by the National Science Foundation (NSF) Advanced Manufacturing program.

Story 3: Researchers make ‘green’ [modular] floor to replace steel [in multistory buildings]

Source: Oak Ridge National Laboratory News

Link: https://www.ornl.gov/news/researchers-make-green-floor-replace-steel

- Researchers at the Department of Energy’s Oak Ridge National Laboratory and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel. The team calls the floor panel a Nfloor cassette panel.

- The goal is to replace traditional steel-and-concrete floor surface assemblies in multistory buildings.

- The project is part of the Sustainable Materials & Manufacturing Alliance for Renewable Technologies, or SM2ART, program. The SM2ART team previously constructed BioHome3D, the nation’s first additively manufactured home made entirely from biologically based materials. [We covered this news previously]

- BioHome3D’s components and the floor panel were recently displayed during the U.S. Dept. of Housing and Urban Development’s 2024 Housing Innovation Showcase on the National Mall.

- As mentioned before, the SM2ART Nfloor cassette panel was developed to replace traditional steel-and-concrete surface assemblies as a transformative step for constructing apartment and condominium buildings.

- The SM2ART floor cassette’s sturdiness comes from its unique formulation of polylactic acid, or PLA, which is a biodegradable thermoplastic-polyester bioplastic derived from corn residue and wood flour made from the waste of lumber processing.

- The technology has the potential to create strong, biologically based sections that could make multistory buildings more environmentally friendly. It could also help increase the use of sustainable structures that are made in a modular construction facility.

- Oak Ridge National Laboratory researcher Katie Copenhaver said this first effort to make a strong building floor panel from green resources significantly advances the potential for increasing the use of organic materials in modular, multiresidential buildings.

- She noted, “By utilizing bio-based, large-scale 3D printing, we replaced an assembly made from 31 parts and three materials with a single-material floor panel that is ecologically friendly, and with the same strength as traditional steel floor fabrication.”

- Here’s how the SM2ART Nfloor was built:

- To construct the floor panel, researchers used a large-scale 3D printer to deposit the PLA/wood flour mixture in a precise, geometric shape.

- By working continuously and autonomously, the printer produced the SM2ART Nfloor cassette at scale, layer upon layer, in about 30 hours.

- The process created a labor-savings of about 33% compared to the effort needed to construct a similar steel floor assembly by hand.

- More on the SM2ART program:

- Established in 2016, SM2ART has seamlessly integrated the expansive advanced manufacturing capabilities of Oak Ridge National Laboratory with the specialized expertise in bio-based composites from the University of Maine Advanced Structures and Composites Center. Evolving from this collaborative foundation, SM2ART has forged more than 50 industry partnerships across the country.

- SM2ART is supported by DOE’s Advanced Materials and Manufacturing Technologies Office and has the following goals:

- Developing platform technologies for functionalized, bio-based composites that are optimized for advanced manufacturing.

- Transforming and expanding existing bio-materials supply chains to enable low-cost materials.

- Expanding on a strong culture of industrial collaboration to leverage leading world-class research and deployment institutions and spin off next-gen technologies.

- Demonstrating and scaling-up sustainable materials and net-zero manufacturing.

- Leveraging workforce development programs to build next-generation leaders through experiential learning and entrepreneurial training programs

Story 4: Researchers [repurpose a video gaming device to] develop technology that may allow stroke patients to undergo rehab at home

Source: MedicalXpress Story from NYU Tandon School of Engineering

Link: https://medicalxpress.com/news/2024-06-technology-patients-rehab-home.html

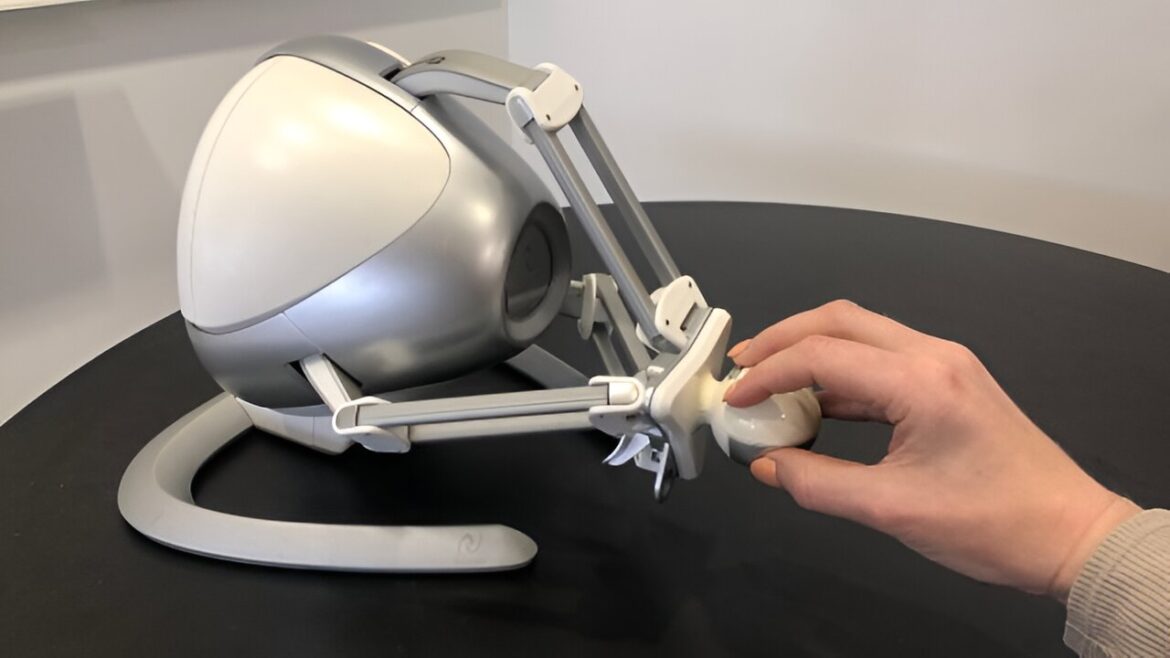

Shown on the left is the device when used for gaming.

- For survivors of strokes, which afflict nearly 800,000 Americans each year, regaining fine motor skills like writing and using utensils is critical for recovering independence and quality of life. But getting intensive, frequent rehabilitation therapy can be challenging and expensive.

- Now, researchers at NYU Tandon School of Engineering are developing a new technology that could allow stroke patients to undergo rehabilitation exercises at home by tracking their wrist movements through a simple setup: a smartphone strapped to the forearm and a low-cost gaming controller called the Novint Falcon.

- The Novint Falcon, a desktop device typically used for video games, can guide users through specific arm motions and track the trajectory of its controller. But it cannot directly measure the angle of the user’s wrist, which is essential data for therapists providing remote rehabilitation.

- In a paper published in Soft Mechatronics and Wearable Systems the NYU researchers proposed using the Falcon video gaming device in tandem with a smartphone’s built-in motion sensors to precisely monitor wrist angles during rehab exercises.

- The researchers collected data from a healthy subject performing tasks with the Falcon while wearing motion sensors on the forearm and hand to capture the true wrist angle. They then trained an algorithm to predict the wrist angles based on the sensor data and Falcon controller movements.

- The resulting algorithm could predict wrist angles with over 90% accuracy, a promising initial step toward enabling remote therapy with real-time feedback in the absence of an in-person therapist.

- Roni Barak Ventura, the paper’s lead author noted, “This technology could allow patients to undergo rehabilitation exercises at home while providing detailed data to therapists remotely assessing their progress. It’s a low-cost, user-friendly approach to increasing access to crucial post-stroke care.”

Honorable Mentions:

Story: A big boost for a climate solution: electricity made from the heat of the Earth

Source: Associated Press Story by Jennifer McDermott

- One method of making electricity cleanly to address climate change has been quietly advancing and on Tuesday it hit a milestone.

- A California utility is backing the largest new geothermal power development in the U.S. — 400 megawatts of clean electricity from the Earth’s heat — enough for some 400,000 homes.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Intel says its optical interconnect chiplet technology is a milestone in high-speed data transmission

Source: TechSpot.com Story by Skye Jacobs

- THE BIG PICTURE: Intel has developed a fully integrated optical compute interconnect (OCI) chiplet, which it compares to transitioning from horse-drawn carriages to cars and trucks in terms of data transmission. The OCI addresses a gap in optical input/output solutions, where some don’t deliver enough reach while others have the reach but at too high a power cost.

- At the Optical Fiber Communication Conference 2024, Intel demonstrated what it calls a revolutionary milestone in integrated photonics technology for high-speed data transmission: a fully integrated optical compute interconnect (OCI) chiplet co-packaged with an Intel CPU and running live data. It is designed to enable co-packaged optical input/output (I/O) in emerging AI infrastructure for data centers and high-performance computing applications.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Electric car battery charges in under five minutes in track test

Source: BBC Story by Zoe Kleinman

Link: https://www.bbc.com/news/articles/cz9dp3ye77do

- An electric car battery developed by UK start-up Nyobolt has successfully charged from 10% to 80% in four minutes and 37 seconds in its first live demonstration.

- It was achieved with a specially-built concept sports car on a test track in Bedford, and is part of industry-wide efforts to get electric vehicles (EVs) charging more quickly.

- By comparison, an existing Tesla supercharger can charge a car battery to 80% in 15-20 minutes.

- Experts say eliminating so-called “range anxiety” is key to increasing uptake of EVs – but also stress the importance of improving the charging infrastructure.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Revolutionizing Medical Implants with Soft Robotics

Source: AZO Robotics Story by Muhammad Osama

Link: https://www.azorobotics.com/News.aspx?newsID=14970

- In a recent article published in the journal Nature Communications, researchers introduced an innovative design strategy for soft robots that mimic the integration of skeletal muscles and sensory skins in living organisms. They demonstrated examples of robotic implants capable of sensing various stimuli and responding with on-demand actuation inside the body.