Show Notes 30 September 2022

Ralph Bond | Tech Reporter KEX & Computer America

Story 1: Denmark and Germany are building an amazing under sea rail and car tunnel

Source: CNN Story by Jacopo Prisco

Link: https://www.cnn.com/travel/article/fehmarnbelt-longest-immersed-tunnel-cmd/index.html

See video here: https://www.youtube.com/watch?v=9Cb6CRJwixw

See video here: https://www.youtube.com/watch?v=zf7C5DiEVpA

- Now under construction, and scheduled to open in 2029, is what will be the world’s longest immersed car and rail tunnel spanning the Baltic Sea between northern Germany and Denmark’s Lolland Island. The key word here is “immersed” – let me explain:

- Unlike the famous “Chunnel” dug under the bottom of the English Channel, this new “tunnel” system will be comprised of 89 massive cast concrete sections [measuring 217 meters long, that’s 712 feet] that will be fabricated on land, and then towed sequentially out to sea.

- Each segment weights more than 73,000 tonnes and is cast incrementally over a skeleton of reinforcing steel in large casting molds.

- A tonne, also known as a metric ton, is a unit of measurement equal to 1,000 kilograms. A metric tonne is larger than a U.S. ton.

- When a segment is completed on land, and ready to be towed out to sea, each end of the segment will be sealed with a bulkhead.

- Each section will then be immersed about 130 feet below the surface to rest on a 12-meter-deep trench dredged on the seabed – and then connected together!

- It’s a brilliant scheme that dramatically cuts cost and time as opposed to digging under the sea floor.

- The trench, by the way, is dug deep enough so that the top of the tunnel segments matches the level of the natural seabed. The plan calls for stone to be coated over the top of the tunnel. Over time, sand will naturally cover the stones to recreate a natural sea floor, and the return of sea plants. Basically, after a few years you would not know the tunnel was just below the sea floor.

- Called the Fehmarnbelt Fixed Link, the 11.1 miles long tunnel will have two double-lane car motorways and two electrified rail tracks separated by a service passageway – making it the longest combined road and rail tunnel in the world.

- After more than a decade of planning, construction started on the tunnel in 2020 and in the months since a temporary harbor and construction facility has been completed on the Danish side. The construction site is now Europe’s largest civil engineering facility, and the world’s largest concrete production facility.

- The tunnel has a construction budget of more than 7 billion euros.

- Today the crossing takes 45 minutes by ferry. When the tunnel is opened it will take just seven minutes by train and 10 minutes by car.

- By the beginning of 2024, the team plans to immerse the first tunnel segment.

Story 2: Future Astronauts Could Use Dust on Mars to 3D-Print Tools and Replacement Parts

Source: Newsweek Story by Pol Allingham and Zenger News

Link: https://www.newsweek.com/tools-could-3d-printed-using-dust-mars-study-reveals-1744485

See video here: https://www.youtube.com/watch?v=wR1xyrI5Vsc&t=1s

- In addition to oxygen, water, food, and buildings long-term occupation of Mars will require the fabrication of tools and replacement parts on site.

- Researchers at Washington State University recently demonstrated the potential for astronauts to 3D-print tools on Mars made from the planet’s dust.

- It’s a significant discovery because NASA can’t transport everything they’ll need from the Earth to Mars.

- And on top of that, transporting materials to Mars would be hugely expensive.

- For example, it costs $54,000 to put just 2 pounds of material into the Earth’s orbit.

- And the cost to deliver materials to Mars would be, of course, exponentially higher.

- To help solve this problem the Washington State University team discovered that small amounts of simulated crushed Martian rock, mixed with a titanium alloy, made a strong, high-performance material that could be used to 3D-print tools and equipment parts on the Red Planet.

- The researchers 3-D printed tools using between 5 and 100 percent simulated Martian regolith, a black powdery substance intended to imitate the rocky, inorganic soil and dust on the surface of Mars that could be collected by a robotic arm or rover.

- They believe this Martian dust only, or titanium and dust combinations could be used to build lightweight tools capable of carrying heavy loads and a host of equipment replacement parts as needed.

Story 3: Air Canada orders 30 electric-hybrid planes with a potential range of up to 500 miles

Source: InterestingEngineering.com Story by Ameya Paleja

Link: https://interestingengineering.com/transportation/air-canada-orders-30-electric-hybrid-planes

- The 30 hybrid electric aircraft Air Canada just ordered are from Sweden-based Heart Aerospace.

- Capable of flying on battery power alone, the 30-passenger planes designed for short distance routes will be propelled by four, low noise, electric propeller motors, with a service ceiling of 20,000 feet.

- At takeoff, when the Heart Aerospace aircraft is powered by batteries alone, it will have a range of about 124 miles.

- After the initial battery powered range of 124 miles is reached, a reserve hybrid mode takes over – much like a car’s hybrid mode. The combination of fuel-based turbogenerators and batteries delivers an additional range of 124 miles.

- And for additional climate friendliness, the turbogenerators can use sustainable “green” fuels.

- And when using non-fossil fuel in reserve-hybrid turbogenerator mode the plane can achieve up to a 90 percent reduction in emissions as compared to a traditional turboprop plane of comparable size.

- And if the passenger load is reduced from 30 to 25, the range can be doubled to nearly 500 miles, according to the Heart Aerospace team.

- And get this, the plane’s batteries can be charged in just 30 minutes for super-fast service turnaround!

Story 4: Scientists create solar-powered robots smaller an ant’s head that can move and “think” on their own

Source: ScienceDaily.com

Link: https://www.sciencedaily.com/releases/2022/09/220921210054.htm

See video here: https://www.youtube.com/watch?v=bCjnekohBAY

- Cornell University researchers have installed electronic “brains” on solar-powered robots that are 100 to 250 micrometers in size — smaller than an ant’s head — so that they can walk autonomously without being externally controlled.

- To date, making ultra-tiny robots that can crawl, swim, walk or fold themselves has been done using magnetics, or wires to provide an electrical current to generate motion, or even laser beams focused directly onto specific locations on the robots.

- Cornell’s tiny solar-powered experimental robot is wireless and has a programmable brain chip to direct its movements for itself!

- The “brain” in the new robots is a complementary metal-oxide-semiconductor (CMOS) clock circuit that contains a thousand transistors, plus an array of diodes, resistors, and capacitors.

- This innovation sets the stage for a new generation of tiny robot devices that can potentially track bacteria, sniff out chemicals, destroy pollutants, conduct microsurgery, and even

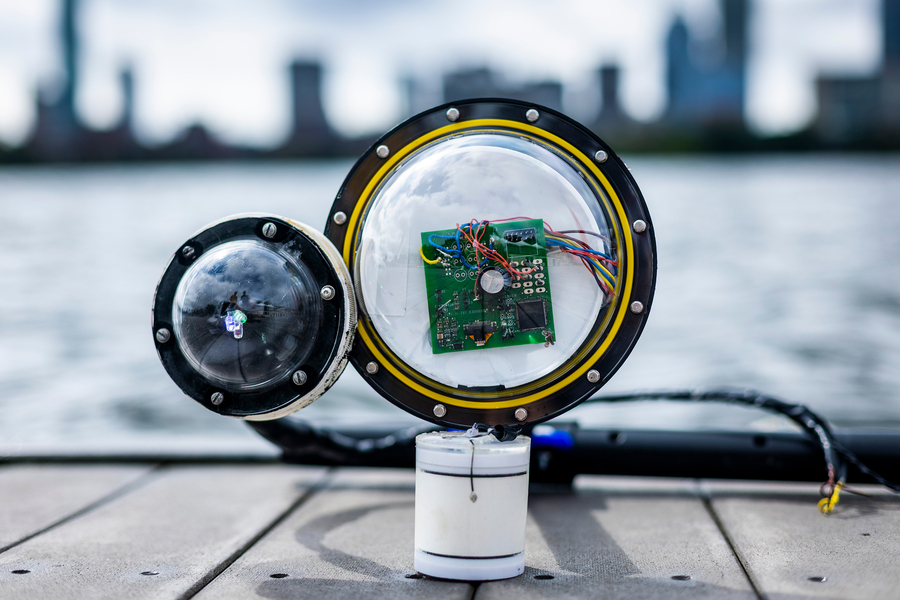

Story 5: MIT engineers build a battery-free, wireless underwater camera

Source: Adam Zewe | MIT News Office