Show Notes January 12, 2024

3 Science/Tech at CES 2024 that caught my eye:

Headline: An instrument more sensitive than a canine’s nose developed by the Pacific Northwest National Laboratory

Source: The Pacific Northwest National Laboratory

Link: https://www.pnnl.gov/events/pnnl-ces-2024

- The Pacific Northwest National Laboratory [part of the US Department of Energy] this week showcased technology and software available for licensing as part of the Department of Energy Office of Technology Transitions booth at the 2024 CES.

- Some of the technology highlighted included:

- An instrument developed at the Pacific Northwest National Laboratory is more sensitive than a canine’s nose and identifies explosives and narcotics vapors in real time at levels previously undetectable by other conventional sampling technologies. See video here: https://www.youtube.com/watch?v=VX07Uje9ZLs

- Side note: Dogs have a much more powerful sense of smell than humans. While humans have about 5 million olfactory receptors, dogs have between 125 million and 300 million 123. This means that dogs can smell things that are much fainter than humans can. For example, dogs can smell a single drop of perfume in an entire swimming pool 4.

Headline: Science and Technology Directorate of the Department of Homeland Security showcased a variety of programs and technologies at CES

Source: Department of Homeland Security website

Link: https://www.dhs.gov/science-and-technology/ces-2024

- At this week’s CES the Science and Technology Directorate of the Department of Homeland Security highlighted its Silicon Valley Innovation Program which bridges the technology development gap between the Department of Homeland Security, startups and small businesses….

- One of the innovative companies/technologies highlighted included myLanguage.

- myLanguage is a mobile language translation company developing technology that enables people to have a fluent spoken conversation with someone who speaks a different language without requiring an Internet connection.

- They are currently working to enable US Coast Guard personnel to communicate in real time rapidly and effectively with non-English speakers and those who are unable to communicate verbally.

Headline: Crowdfunded hiking exoskeleton debuted this week at CES

Source: GlobalData via MSN Story by Sarah Brady

Link: https://www.msn.com/en-us/news/technology/crowdfunded-hiking-exoskeleton-set-for-debut/ar-AA1mpXgJ

See video here: https://www.youtube.com/watch?v=vDbSlarxb-k

- Shanghai-based exoskeleton company Hypershell debuted its new exoskeleton product this week at CES 2024.

- The company’s exoskeleton product, touted as smart and lightweight, caters to the needs of outdoor enthusiasts requiring additional support or those carrying heavy loads.

- The wearable device offers a 25km battery range [15.5 mile range], a maximum speed of 20 km/h [12.4 miles per hour], and the ability to offset 30kg of weight [66 pounds] through its one-horsepower mechanism and 14 artificial intelligence sensors adapting to users’ movements.

- Equipped with an AI-based motion engine, the exoskeleton adapts to the user’s movements, providing assistance with a maximum power of 800 W.

Story 2: eVince microreactor boasts 8+ years of nuclear power without using water

Source: Interesting Engineering Story by Ameya Paleja

Link: https://interestingengineering.com/innovation/microreactor-no-water-for-operation

See video here: https://www.youtube.com/watch?v=u7zNs2nueQM

- Side note – what are microreactors? A nuclear microreactor is a type of nuclear reactor that is designed to generate electricity on a smaller scale than traditional nuclear reactors. They are 100 to 1,000 times smaller than conventional nuclear reactors….

- See: https://www.energy.gov/ne/articles/what-nuclear-microreactor and https://en.wikipedia.org/wiki/Nuclear_microreactor

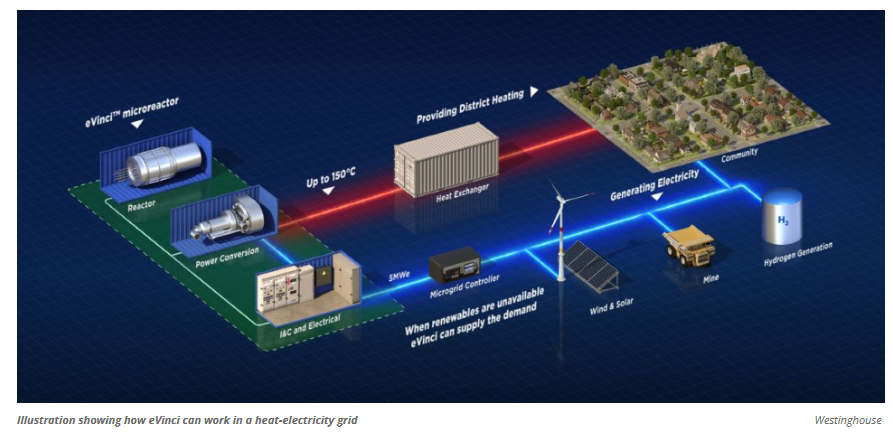

- A new microreactor, eVinci, developed by Westinghouse, has an amazing feature. It can function without water, paving the way for nuclear power to reach far-off locations where water might be scarce. The first such microreactor will come up in Saskatchewan, Canada, by the end of this decade.

- Unlike nuclear power plants, which often take years to build and become operational, microreactors offer a rapid way to transport and set up a power plant using nuclear fuel. As the name suggests, a microreactor is small enough to fit a transport truck or aircraft and can be quickly moved to a place in need of electricity.

- However, most microreactor designs still require water either to convey heat from the core to steam turbines or to remove excess heat. eVinci’s unique attribute is that it does not use water at all in its operation.

- Westinghouse claims to have achieved this using “Heat Pipe technology,” which decreases the number of components needed in active systems.

- Recently, the team manufactured its first ever 12-foot (3.6 m) long nuclear grade heat pipe, which eliminates the risks from high pressure or cooling leak incidents seen in other designs, the company said on its webpage.

- The company also uses a Passive Heat Removal System which deploys radiation and convection modes of heat transfer to remove heat from the reactor core without any need for operator intervention.

- The heat removed from the reactor can be used either for district heating or for industrial applications, depending on the environment it is operating in.

- Westinghouse uses TRISO fuel [TRi-structural ISOtropic particle fuel] in the eVinci, which is more resistant to incidents of corrosion, oxidation, and high temperatures than traditional nuclear fuels.

- The microreactor does not require refueling and can work for more than eight years, producing 5 Megawatts of energy while reducing 55,000 tons of C02/per year.

- Side note, what is TRISO fuel? TRISO stands for TRi-structural ISOtropic particle fuel. Each TRISO particle is made up of a uranium, carbon and oxygen fuel kernel. The kernel is encapsulated by three layers of carbon- and ceramic-based materials that prevent the release of radioactive fission products. Source: https://www.energy.gov/ne/articles/triso-particles-most-robust-nuclear-fuel-earth

- Once the fuel is exhausted, the microreactor can be hauled away for disposal and another one plugged in its place to continue operations on-site, much like a battery.

- Earlier in November this year [2023], the Saskatchewan Research Council (SRC) approved a CAD 80 million (US$59 million) project to build the first such microreactor in Canada. The facility is expected to be operational by 2029.

Story 3: The British start-up plotting to make computer chips in space

Source: The Telegraph Story by Howard Mustoe

- Making computer chips from materials forged in space may sound like an idea from a science fiction novel, but a British company is hoping to make it a reality.

- Space Forge plans to send small, washing machine-sized modules into low earth orbit, about 500-800 km [up to 497 miles] above the surface of the earth, where gravity is low but retrieval is within reach.

- Low gravity means the raw materials for semiconductor computer chips can be made more easily.

- Josh Western, Space Forge’s founder, says: “A combination of the microgravity and the vacuum you find in space allows you to create incredibly pure crystal structures. Space effectively allows crystals to bond better with less contaminants.”

- While most chips are made of silicon, Space Forge is exploring the use of alternative materials such as gallium nitride. The full chip won’t be made in space, just the raw material.

- Higher crystal purity means chips will produce less waste heat, which could save millions of dollars when operated. And the amount of energy use could be slashed by up to 60 percent.

- The Space Forge team hopes the technology will lead to significant savings for applications such as 5G phone masts, radar, and electric car charging.

- The company’s [space] lab can be launched by rockets such as those operated by Elon Musk’s SpaceX. Once the process of forming the crystals is complete, the aim is for the module to be returned to earth “like Mary Poppins” with a deployable umbrella to slow its reentry, Western says.

- The cost will be significant, but the final price will depend on the complexity of the chip materials, how long the module stays in space and how many microchips a customer wants.

- Once a batch of chips have been made in space, the material can be used to “seed” cheaper manufacturing processes on earth. This lowers the cost of production dramatically while retaining most of the benefits.

Story 4: Researchers develop sustainable wound dressing hydrogel based on seaweed and carbonated water

Source: Phys.org Story by Science X staff

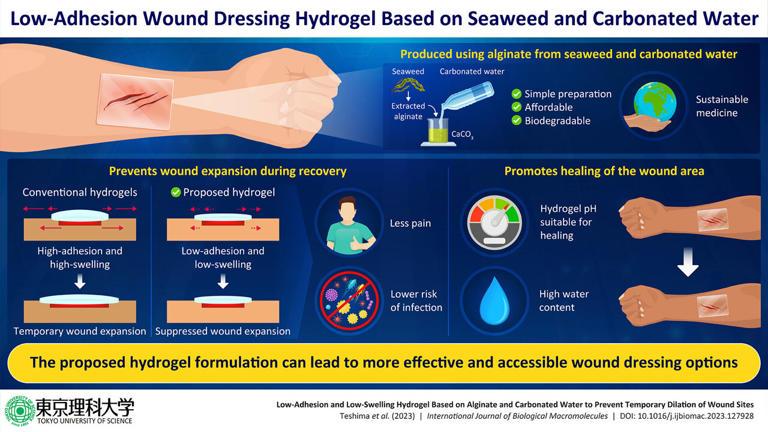

- Over the past few decades, hydrogels have received a lot of attention for treating skin wounds. When applied over a lesion, these special gels can promote healing by absorbing discharged fluids and keeping the wound protected, well-hydrated, and oxygenated.

- However, most developed hydrogels are given adhesive properties to skin tissue to follow skin movement. Since these hydrogels are sticky and adhere to the skin and wound site, they stretch and expand the wound itself once they swell up after absorbing fluids.

- This not only causes pain to the user but also puts them at a higher risk of bacterial infection due to the wound area expansion.

- Against this backdrop, a team of researchers from Tokyo University of Science, Japan, have now proposed an innovative and highly-value added medical material for treating skin wounds.

- As reported in their recent study published in the International Journal of Biological Macromolecules, they developed a novel, low-cost hydrogel using a component found in seaweed, achieving physical properties utterly different from those of conventional hydrogels.

- The method of preparation of the proposed hydrogel is quite straightforward. It was made using alginate, calcium carbonate, and carbonated water. Alginate is a biocompatible substance that can be extracted from beach-cast seaweed.

- Most importantly, it does not adhere strongly to cells or skin tissues. Thanks to the special structure formed by alginate and calcium ions, in addition to the protective effect of the CO2 in carbonated water against acidification, the resulting hydrogel not only exhibited ideal pH and moisture conditions for wound recovery but also demonstrated significantly lower adhesion and swelling, compared to other commercial hydrogel wound dressings.

HONORABLE MENTIONS:

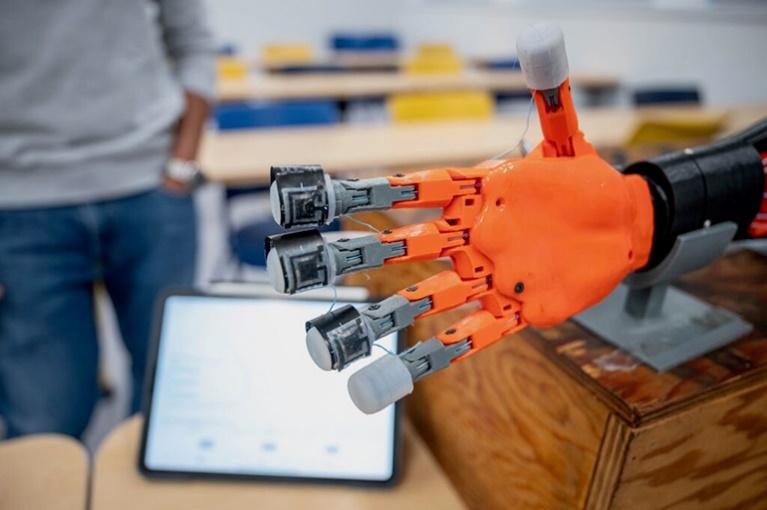

Story: Stretchable E-Skin for Robotic Prostheses

Source: Medgadget.com Story by Conn Hastings

Link: https://www.medgadget.com/2023/11/stretchable-e-skin-for-robotic-prostheses.html

Note: This is news from late November of last year, but I wanted to highlight this development.

- Engineers at the University of British Columbia have collaborated with the Japanese automotive company Honda to develop an e-skin for robotic prostheses that allows such devices to sense their environment in significant detail.

- The soft skin is highly sensitive, letting robotic hands to perform tasks that require a significant degree of dexterity and tactile feedback, such as grasping an egg or lifting a glass of water without breaking it.

- The elastomer skin contains fixed and sliding pillars that allow it to buckle and wrinkle, like real skin. The skin contains four deformable capacitators that let it distinguish between normal and shear forces, meaning that it can finely control its interaction with grasped objects.

- The researchers hope that the technology will enhance robotic prostheses and allow users to expand the range of daily activities they can perform using their prosthetic devices.

- This latest e-skin is highly sensitive, expanding the types of activities that are possible. “Our sensor can sense several types of forces, allowing a prosthetic or robotic arm to respond to tactile stimuli with dexterity and precision,” said Mirza Saquib Sarwar, a researcher involved in the study. “For instance, the arm can hold fragile objects like an egg or a glass of water without crushing or dropping them.”

- The technology may also be useful for medical or assistive robots, such as those that care for the elderly, or even surgical robots that interact with soft tissues inside the body. “Our sensor uses weak electric fields to sense objects, even at a distance, much as touchscreens do,” said John Madden, another researcher involved in the study. “But unlike touchscreens, this sensor is supple and can detect forces into and along its surface. This unique combination is key to adoption of the technology for robots that are in contact with people.”

- The skin is easy to fabricate at scale and can be made in large sheets that can cover significant areas. However, the researchers are keen to stress that this technology will evolve much further in the future.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Amazon plans to make its own hydrogen to power vehicles

Source: TheVerge.com Story by Justine Caima

Link: https://www.theverge.com/2023/12/28/24017535/amazon-fulfillment-center-warehouse-hydrogen-fuel-plug

- Amazon is making plans to produce hydrogen fuel at its fulfillment centers. The retail behemoth partnered with hydrogen company Plug Power to install the first electrolyzer — equipment that can split water molecules to produce hydrogen — at a fulfillment center in Aurora, Colorado.

- The electrolyzer will make fuel for around 225 fork lift trucks at the site, although Plug says it has the capacity to fuel up to 400 hydrogen fuel cell-powered forklifts. This is the first time Amazon has tried to make its own hydrogen on site, and it’s not likely to be the last.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

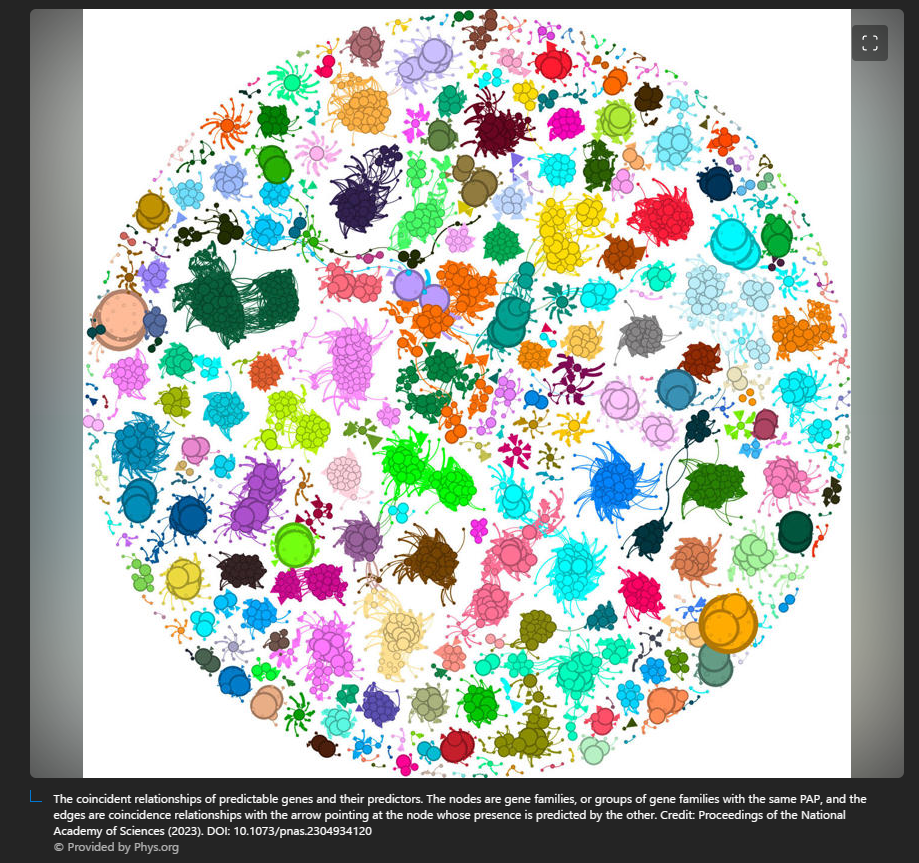

Story: Evolution is not as random as previously thought, finds new study

Source: Phys.org Story by Science X Staff

- A new study has found that evolution is not as unpredictable as previously thought, which could allow scientists to explore which genes could be useful to tackle real-world issues such as antibiotic resistance, disease, and climate change.

- The study, which is published in the Proceedings of the National Academy of Sciences (PNAS), challenges the long-standing belief about the unpredictability of evolution and has found that the evolutionary trajectory of a genome may be influenced by its evolutionary history, rather than determined by numerous factors and historical accidents.