Story 1: The company Bill Gates just backed is aiming to revolutionize air travel with a surprising resource.

Source: The Cool Down Story by Jeremiah Budin

See also Viridos website https://www.viridos.com/

And video here: https://m.facebook.com/ViridosNews/videos/watch-viridos-scientist-william-lambert-explain-how-photosynthesis-can-play-a-cr/1330048914407019/

- The need to revolutionize the air travel industry is clear, as aviation accounts for 2.5% of all global planet-overheating pollution, and passenger air travel represents the highest amount of pollution per individual user of any industry.

- One startup is seeking to change that, and it recently received a substantial investment from Microsoft founder Bill Gates to help it in its mission.

- Viridos, a California-based company that was founded in 2011, focuses on turning microalgae into biofuel. The company hopes that its products can eventually become dense and energy-intensive enough to power airplanes and ocean vessels.

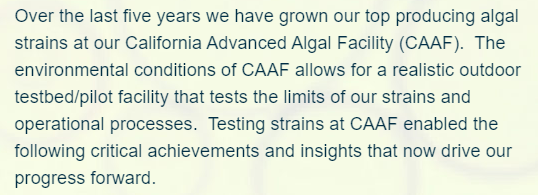

- Side note, what are microalgae? Microalgae are microscopic algae invisible to the naked eye. They are phytoplankton typically found in freshwater and marine systems, living in both the water column and sediment. They are unicellular species which exist individually, or in chains or groups.

Microalgae

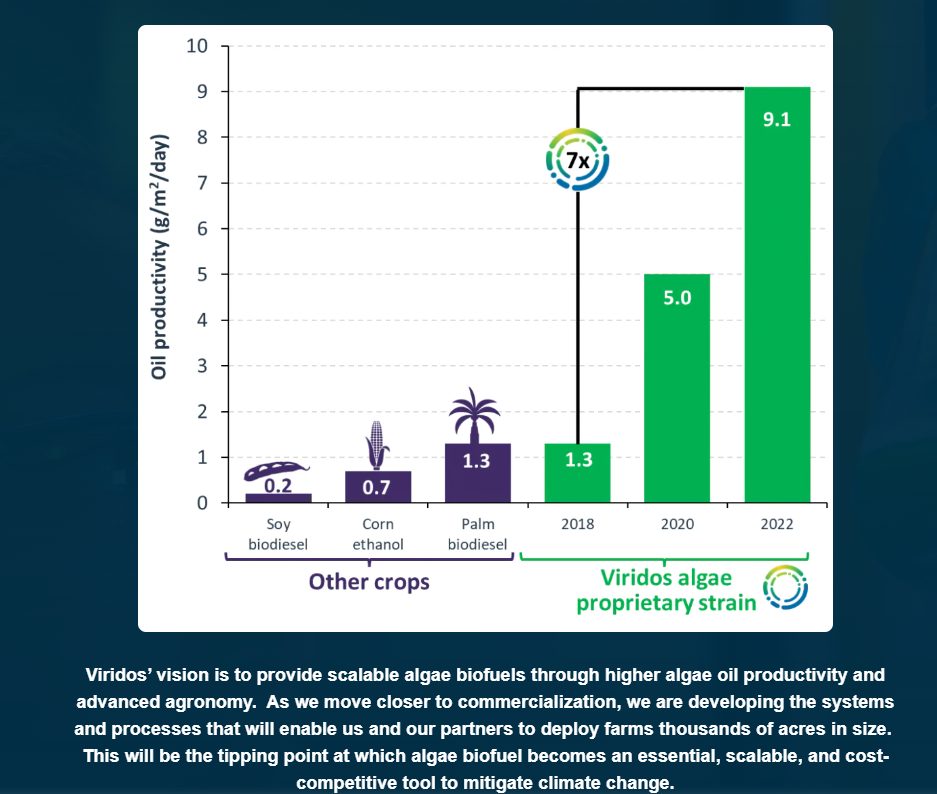

- Viridos has developed a proprietary process that combines sunlight and carbon dioxide to produce microalgae, which is then converted into biofuel. This gives the company an advantage over other biofuel makers that rely on ethanol (corn) and soy biodiesel (soy). Instead of competing for crops that are part of the food supply, Viridos can simply generate its own material with minimal freshwater and no farmland required.

- More from the Viridos website:

- We believe that high-energy density algae biofuel for heavy transportation is part of the answer. By establishing this non-resource intensive, breakthrough solution deployed at a global scale, we can recalibrate heavy transportation toward a more sustainable future.

- We are developing an advanced microalgae strain and agronomic platform to produce biofuels for deployment at scale.

- Side note, what is “agronomic”? It’s a branch of agriculture dealing with field-crop production and soil management.

- By capitalizing on well-established regulatory programs that incentivize adoption, such as the Environmental Protection Agency’s Renewable Fuel Standard Program and California’s Low Carbon Fuel Standard in the US, and the Renewable Energy Directive in Europe, we can make the adoption of microalgae biofuels more attractive and establish a more level playing field.

- Microalgae are excellent at converting CO2 and sunlight into oil-rich biomass, especially when compared to land-based crop plants like oil palm and soy. By adapting microalgae to function as cell factories producing energy-dense oils that can easily be refined into renewable diesel and jet fuel, we can reduce greenhouse gas emissions by 70%.

- By farming in saltwater on marginal land, we avoid competing with resources required for food production, such as arable farmland and freshwater.

- We estimate that at commercialization, the productivity of engineered microalgae will be 20x times greater than any existing terrestrial crop. This dramatic advantage underpins the scalability of our technology.

Story 2: At the Speed of Light: Unveiling the Chip That’s Reimagining AI Processing

Source: SciTechDaily Story from University of Pennsylvania

Link: https://scitechdaily.com/at-the-speed-of-light-unveiling-the-chip-thats-reimagining-ai-processing/

See video here: https://www.youtube.com/watch?v=feplkkP7n5c&t=3s

- University of Pennsylvania engineers have developed a new chip that uses light waves, rather than electricity, to perform the complex math essential to training AI. The chip has the potential to radically accelerate the processing speed of computers while also reducing their energy consumption.

- The silicon-photonic (SiPh) chip’s design is the first to bring together University of Pennsylvania Professor Nader Engheta’s pioneering research in manipulating materials at the nanoscale to perform mathematical computations using light — the fastest possible means of communication — with the silicon-photonic platform, which uses silicon, the cheap, abundant element used to mass-produce computer chips.

- Side note about Nader Engheta – Nader Engheta is the H. Nedwill Ramsey Professor at the University of Pennsylvania in Philadelphia, with affiliation in the Departments of Electrical and Systems Engineering (primary appointment), Bioengineering (secondary appointment), Physics and Astronomy (secondary appointment), and Materials Science and Engineering (secondary appointment).

Nader Engheta

- The interaction of light waves with matter represents one possible avenue for developing computers that supersede the limitations of today’s chips, which are essentially based on the same principles as chips from the earliest days of the computing revolution in the 1960s.

- In a paper published February 16 in Nature Photonics, Engheta’s group, together with Firooz Aflatouni, Associate Professor in Electrical and Systems Engineering, describes the development of the new chip. “We decided to join forces,” says Engheta, leveraging the fact that Aflatouni’s research group has pioneered nanoscale silicon devices.

Firooz Aflatouni

- Their goal was to develop a platform for performing what is known as vector-matrix multiplication, a core mathematical operation in the development and function of neural networks, the computer architecture that powers today’s AI tools.

- Instead of using a silicon wafer of uniform height, explains Engheta, “you make the silicon thinner, say 150 nanometers, but only in specific regions. Those variations in height — without the addition of any other materials — provide a means of controlling the propagation of light through the chip, since the variations in height can be distributed to cause light to scatter in specific patterns, allowing the chip to perform mathematical calculations at the speed of light”.

- Their design is ready for commercial applications and could potentially be adapted for use in graphics processing units (GPUs), the demand for which has skyrocketed with the widespread interest in developing new AI systems. “They can adopt the Silicon Photonics platform as an add-on,” says Aflatouni, “and then you could speed up training and classification.”

- In addition to faster speed and less energy consumption, Engheta and Aflatouni’s chip has privacy advantages: because many computations can happen simultaneously, there will be no need to store sensitive information in a computer’s working memory, rendering a future computer powered by such technology virtually unhackable. “No one can hack into a non-existing memory to access your information,” says Aflatouni.

Story 3: 3D-printed human brain tissue works like the real thing.

Source: Live Science Story by Emily Cooke

Source: Futurism Story by Victor Tangermann

Link: https://futurism.com/neoscope/scientists-3d-print-functional-human-brain-tissue

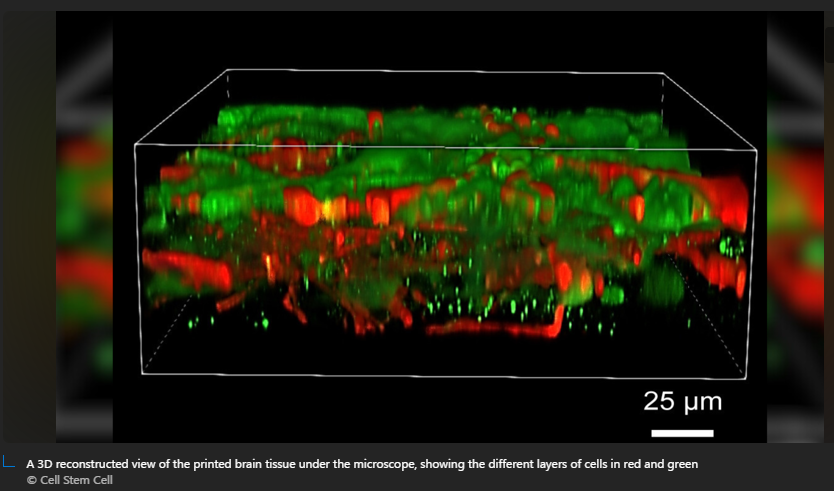

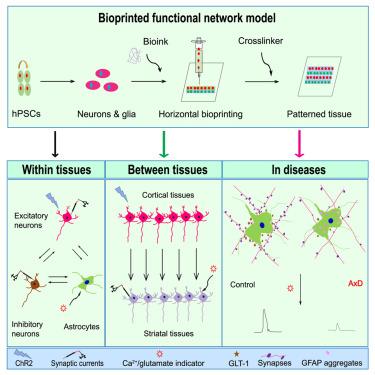

- For the first time, scientists at the University of Wisconsin-Madison have generated functional human brain tissue using a 3D printer.

- Scientists printed the tissue to be less than 0.01 inch (0.02 centimeter) thick, and it contains both nerve cells and supporting cells called glia. All of these cells can communicate with one another and form networks, as they would in a real human brain.

- Side note, what is/are glia? the connective tissue of the nervous system, consisting of several different types of cells associated with neurons.

- The tissue was created using a biological “printer” that churned out stem-cell-laden gel in horizontal layers. The stem cells were then coaxed to become brain cells with chemicals that stimulate this development. The tissue layers were carefully stacked, one by one, on a lab dish to form a complete tissue model.

- The researchers behind the printed tissue described their accomplishment in a paper published Feb. 1 in the journal Cell Stem Cell.

- They hope it will complement other models of the human brain — such as models crafted from actual human cells — to more accurately represent the intricate and unique features of the human brain than traditional animal models do.

- These include so-called brain-on-a-chip technologies, which mimic brain tissue on credit-card-sized devices, and cerebral organoids, which are miniature, simplified models of brains that self-assemble in dishes.

- However, unlike organoids the University of Wisconsin-Madison 3D printing technique gives scientists more control over which cells end up where in the final tissue. Nerves within the printed tissue also form connections with each other within two to five weeks — a process that can take many months in organoids.

- Side note, more on organoids – [An organoid is a miniaturized and simplified version of an organ produced in vitro in three dimensions that mimics the key functional, structural, and biological complexity of that organ].

- Thanks to this speed [again, nerves within the printed tissue also form connections with each other within two to five weeks], different versions of the 3D-printed brain tissue can also be made much more easily than when using organoids.

- As a result, this technology could therefore be particularly useful for testing new drug candidates for diseases that affect brain function, such as neurodegenerative and psychiatric disorders. That’s because the different printed models could be made to display characteristics of each disorder.

- Unlike traditional 3D-printing approaches, which stack layers of material vertically, the authors stacked their gel horizontally. This allowed the layers to be thinner, and thus the cells within them were exposed to as much oxygen and nutrients as possible.

- The printed stem cells developed into full-fledged neurons and glia, which formed networks resembling those found in the human brain, and they even communicated with each other via chemical messengers called neurotransmitters.

- The printed cells that normally belong to different parts of the brain — such as its outer layer, or cortex, and the striatum, which is involved in decision-making — also formed connections with one another.

Story 4: Blood vessels made with 3D-printed ice could improve lab-grown organs – Molds of an organ’s delicate blood vessel network can be made with 3D-printed ice, helping to overcome the intricacies of growing transplant organs in a lab.

Source: NewScientist.com Story by Matthew Sparkes

- First, here’s the challenge that underscores the significance of this news:

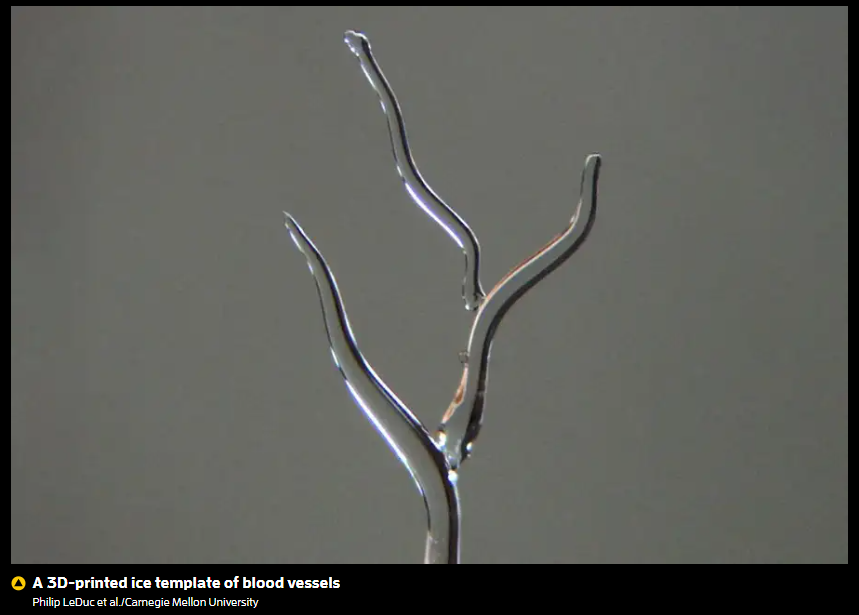

- Researchers have been working on artificial organs for decades to help meet the high global demand for transplants such as hearts, kidneys, and livers. But creating the blood vessel networks needed to keep them alive is still a challenge.

- Existing techniques can, for example, grow artificial skin or ears, but any flesh or organ material dies off if the tissue is more than 200 micrometers [about twice the width of a human hair] from a blood vessel.

- Lab-grown internal organs therefore require new processes to create delicate blood vessels if they are to become less expensive and faster to manufacture.

- Here’s how Carnegie Mellon University in Pennsylvania researchers [headed by Philip LeDuc] have figured out a way to solve this blood vessel networks challenge to help create complex artificial organs:

- First, they 3D printed a mold of veins, arteries, and capillaries in ice.

- Next, they cast that mold in organic material and then allowed the ice to melt away, resulting in a delicate, hollow network.

- This leaves a space for the intricate artificial blood vessels that are required to develop lab-grown internal organs.

- Previously LeDuc and his colleagues experimented with printing blood vessels with wax that can be melted, but this requires reasonably high temperatures and can leave residue.

- LeDuc recalls, “All of a sudden, one day, my student goes ‘why don’t we just use water – the most biologically compatible material in the world? And I’m like ‘oh, yeah’. It still makes me laugh. It’s just so straightforward.”

- They developed a technique that uses 3D printers to create a mold of the interior of an organ’s blood vessels in ice. In tests, these were then embedded in a gelatine material that hardens when exposed to ultraviolet light before the ice melted away.

- The team used a platform cooled to -35°C [-95 degrees Fahrenheit] and a printer nozzle that dispensed hundreds of drops of water a second, allowing structures as small as 50 micrometers across to be printed.

- LeDuc says the process is conceptually simple but needs to be tuned perfectly – if you dispense drops too fast and they don’t freeze quickly enough it will fail to create the desired shape, but print them too slowly and they just form lumps.

- The system is also affected by weather and humidity, so the researchers are investigating using artificial intelligence to keep the printer tuned to varying conditions.

- They also used a version of water in which all the hydrogen is replaced by deuterium, a stable isotope of the element. This so-called heavy water has a higher freezing point and helps to create a smooth structure by avoiding unwanted crystallization. Tests have shown it will be safe when creating artificial organs as deuterium isn’t radioactive, unlike some isotopes, says LeDuc.

Honorable Mentions:

Story: ‘Holy grail for memory tech’: New candidate for universal memory emerges in race to replace RAM and NAND — and this one doesn’t use a toxic compound

Source: TechRadar Story by Wayne Williams

- The current memory market, worth $165bn a year, is dominated by DRAM and NAND flash. The former is fast with excellent endurance but is volatile, requiring constant refreshing of data. The latter on the other hand, is non-volatile, retaining data when unpowered, but is slower and has poor program/erase cycling endurance.

- ULTRARAM, developed by Quinas Technology, a spinoff from Lancaster University in the UK, combines the advantages of both, offering fast, non-volatile memory with high endurance and ultra-low switching energies.

- The technology, which recently won an award at the Flash Memory Summit, boasts superior longevity than flash storage, matches the read/write speeds of system memory, and requires less power.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Yamaha Just Unveiled the World’s First Hydrogen Outboard

Source: Wonderfulengineering.com

Link: http://tinyurl.com/2vtekzhm

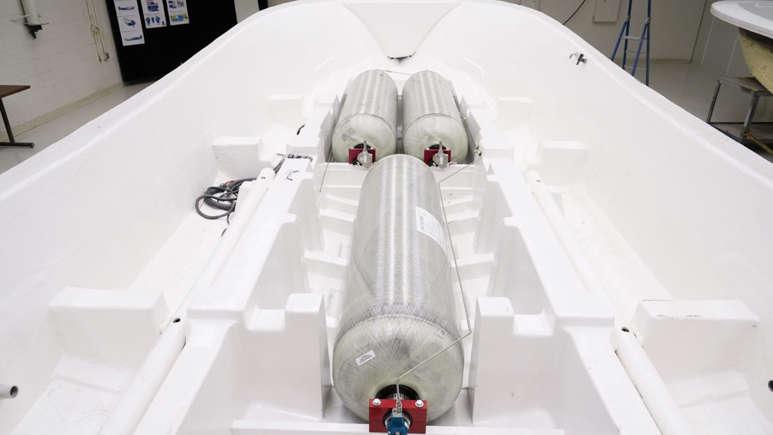

- Yamaha’s unveiling of its prototype hydrogen-combustion outboard motor at the 2024 Miami International Boat Show is a groundbreaking development in recreational boating. This endeavor, announced alongside a prototype boat and fuel delivery system, reflects Yamaha’s commitment to pioneering sustainable marine propulsion solutions. Collaborating with Roush and egulator Marine, Yamaha aims to revolutionize the industry’s approach to power generation.

- The hydrogen outboard represents an adaptation of Yamaha’s land-based hydrogen combustion engine technology, previously showcased in projects like the Drive H2 golf cart concept. Based on Yamaha’s flagship XTO outboard platform, renowned for its power and reliability, the hydrogen variant’s output specifications remain undisclosed. Nevertheless, it promises to offer a compelling alternative to traditional gas-powered engines, potentially reshaping Yamaha’s outboard lineup.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: This baby with a head camera helped teach an AI how kids learn language

Source: MIT Technology Review Story by Cassandra Willyard

Link: https://www.technologyreview.com/2024/02/01/1087527/baby-ai-language-camera/

- Human babies are far better at learning than even the very best large language models. To be able to write in passable English, ChatGPT had to be trained on massive data sets that contain millions or even a trillion words. Children, on the other hand, have access to only a tiny fraction of that data, yet by age three they’re communicating in quite sophisticated ways.

- A team of researchers at New York University wondered if AI could learn like a baby. What could an AI model do when given a far smaller data set—the sights and sounds experienced by a single child learning to talk?

- A lot, it turns out. The AI model managed to match words to the objects they represent. “There’s enough data even in this blip of the child’s experience that it can do genuine word learning,” says Brenden Lake, a computational cognitive scientist at New York University and an author of the study. This work, published in Science today, not only provides insights into how babies learn but could also lead to better AI models.

////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Story: Microsoft Will Use Intel to Manufacture Home-Grown Processor

Source: Bloomberg Story by Ian King

- Intel Corp. has landed Microsoft Corp. as a customer for its made-to-order chip business, marking a key win for an ambitious turnaround effort under Chief Executive Officer Pat Gelsinger.

- Microsoft plans to use Intel’s 18A manufacturing technology to make a forthcoming chip that the software maker designed in-house, the two companies said at an event Wednesday. They didn’t identify the product, but Microsoft recently announced plans for two homegrown chips: a computer processor and an artificial intelligence accelerator.